[1] 王彦芳, 肖丽君, 刘明星, 等. 激光熔覆制备非晶复合涂层的研究进展[J]. 激光与光电子学进展, 2014, 51(7): 070002.

Wang Y F, Xiao L J, Liu M X, et al. Research progress of laser cladding amorphous coatings[J]. Laser & Optoelectronics Progress, 2014, 51(7): 070002.

[2] 翟建华, 刘志杰, 张勇, 等. 内缸活塞杆的激光熔覆修复[J]. 激光与光电子学进展, 2017, 54(11): 111411.

Zhai J H, Liu Z J, Zhang Y, et al. Laser cladding reparation of inner cylinder piston rods[J]. Laser & Optoelectronics Progress, 2017, 54(11): 111411.

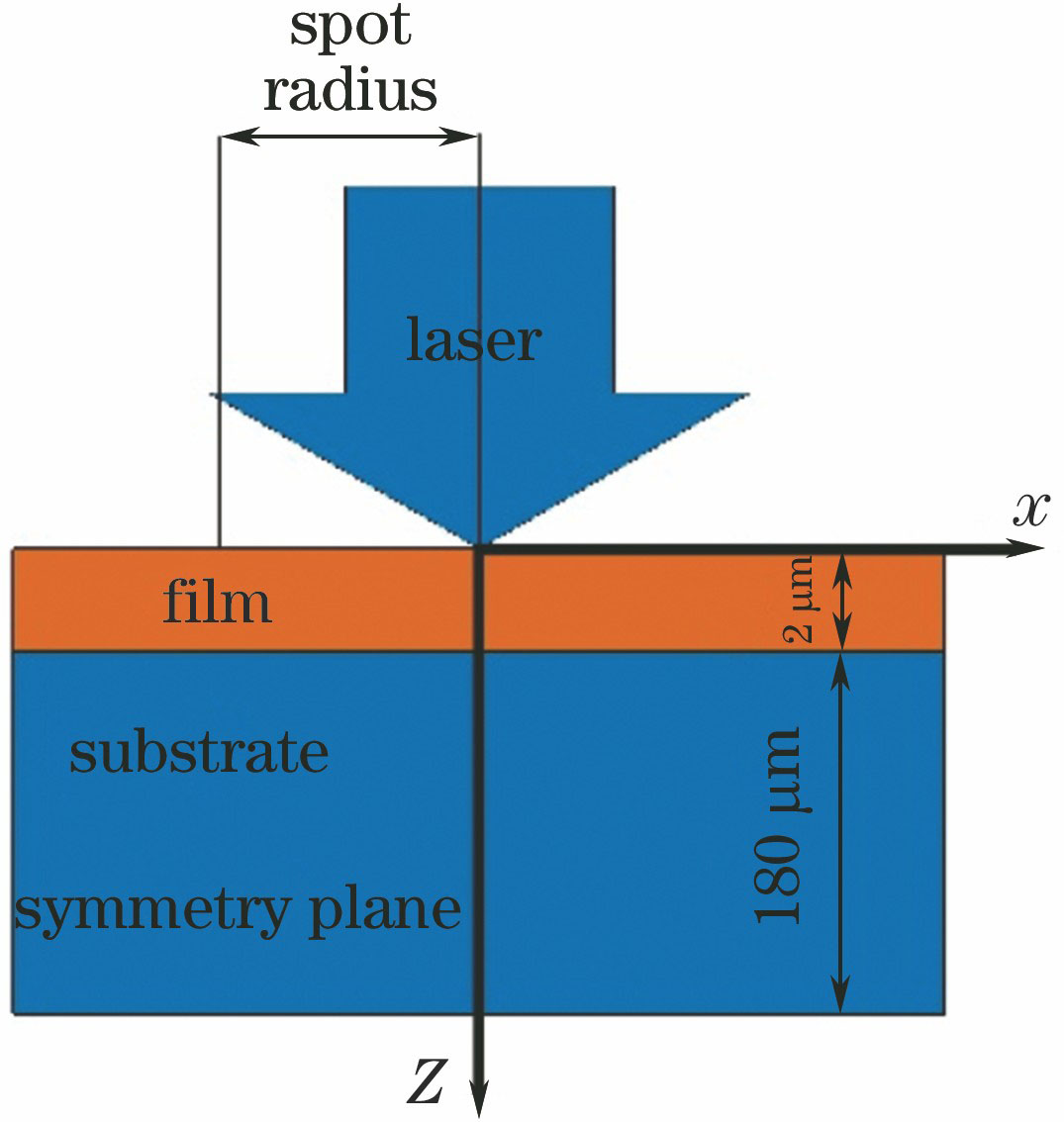

[3] 张永彬, 宾韧, 郎定木. 纳秒脉冲激光熔覆温度场计算及薄膜飞溅机制分析[J]. 应用激光, 2012, 32(6): 464-468.

Zhang Y B, Bin R, Lang D M. Calculation for nano-second pulsed laser cladding temperature field and analysis of thin film removal mechanism[J]. Applied Laser, 2012, 32(6): 464-468.

[4] 余吟山, 游利兵, 梁勖, 等. 准分子激光技术发展[J]. 中国激光, 2010, 37(9): 2253-2270.

Yu Y S, You L B, Liang X, et al. Progress of excimer lasers technology[J]. Chinese Journal of Lasers, 2010, 37(9): 2253-2270.

[5] Kluska S, Granek F. High-efficiency silicon solar cells with boron local back surface fields formed by laser chemical processing[J]. Proceedings of the IEEE, 2011, 32(9): 1257-1259.

[6] Das A, Kim D S, Nakayashiki K, et al. Boron diffusion with boric acid for high efficiency silicon solar cells[J]. Journal of the Electrochemical Society, 2010, 157(6): H684-H687.

[7] Vinodkumar M, Korot K, Limbachiya C, et al. Screening-corrected electron impact total and ionization cross sections for boron trifluoride (BF3) and boron trichloride (BCl3)[J]. Journal of Physics B, 2008, 41(24): 245202.

[8] 宿世超, 王涛, 韩宇哲, 等. 热丝CVD法沉积固态扩散源制备晶硅太阳电池p

+/n

+发射极研究

[J]. 人工晶体学报, 2016, 45(11): 2591-2595.

Su S C, Wang T, Han Y Z, et al. p

+/n

+ emitter of the crystalline silicon solar cell fabricated with solid diffusion source deposited by HWCVD method

[J]. Journal of Synthetic Crystals, 2016, 45(11): 2591-2595.

[9] 李海波,

董经兵,

刘仁中,

等. 一种背结背接触晶体硅太阳电池的硼扩散工艺: CN201310617109.5[P].2014-03-19.

Li HB,

Dong JB,

Liu RZ,

et al. A boron diffusion process for crystalline silicon solar cells with back junction and

back contact:CN201310617109.5[P].

2014-03-19.

[10] 杨楠楠, 沈鸿烈, 蒋晔, 等. 二氧化硅纳米球对硼酸源扩散形成p

+硅层性能的影响

[J]. 材料导报, 2017, 31(12): 11-14.

Yang N N, Shen H L, Jiang Y, et al. Influence of SiO2 nanosphere on the performance of p

+ layer formed by B diffusion from boric acid solution

[J]. Materials Review, 2017, 31(12): 11-14.

[11] 刘奎,

刘雅璇,

牛钧杰,

等.

钛合金表面激光熔覆TiCN涂层及其温度场有限元模拟[J]. 激光杂志,

2016(

8):

27-

32.

LiuK,

Liu YX,

Niu JJ, et al.

Simulation of temperature field distribution finite element during laser cladding TiCN coatings on titanium alloy[J]. Laser Journal,

2016(

8):

27-

32.

[12] 刘娟, 罗开玉, 景祥, 等. 激光熔覆316L不锈钢温度场模拟与分析[J]. 中国激光, 2015, 42(s1): s103002.

Liu J, Luo K Y, Jing X, et al. Simulation and analysis of the temperature field in laser cladding 316L stainless steel[J]. Chinese Journal of Lasers, 2015, 42(s1): s103002.

[13] 刘昊, 虞钢, 何秀丽, 等. 送粉式激光熔覆中瞬态温度场与几何形貌的三维数值模拟[J]. 中国激光, 2013, 40(12): 1203007.

Liu H, Yu G, He X L, et al. Three-dimensional numerical simulation of transient temperature field and coating geometry in powder feeding laser cladding[J]. Chinese Journal of Lasers, 2013, 40(12): 1203007.

[14] 宫新勇, 高士友, 咸士玉, 等. 基于温度特征的单道激光熔覆翘曲变形[J]. 激光与光电子学进展, 2017, 54(10): 101410.

Gong X Y, Gao S Y, Xian S Y, et al. Warp deformation in single-track laser cladding based on temperature characteristics[J]. Laser & Optoelectronics Progress, 2017, 54(10): 101410.

[15] 洪捐.

硼掺杂硅纳米浆料制备及其在高效晶硅太阳能电池背场中的应用基础研究[D].

南京: 南京航空航天大学,

2016:

49-

55.

HongJ.

Preparation of boron doped silicon nano paste and its fundamental research for application in back surface field of high-efficiency silicon solar cells[D].

Nanjing: Nanjing University of Aeronautics and Astronautics,

2016:

49-

55.

[16] 洪捐, 宣容卫, 黄海冰, 等. 皮秒激光熔覆硼掺杂硅纳米浆料的实验研究[J]. 中国激光, 2016, 43(9): 0902006.

Hong J, Xuan R W, Huang H B, et al. B-doped nano-Si-paste by picosecond laser cladding[J]. Chinese Journal of Lasers, 2016, 43(9): 0902006.

[17] Bahrami A, Helenbrook B T, Valentine D T, et al. Fluid flow and mixing in linear GTA welding of dissimilar ferrous alloys[J]. International Journal of Heat and Mass Transfer, 2016, 93: 729-741.

[18] 孙鹏, 李沫, 杨庆鑫, 等. 硅在脉冲激光作用下温度积累效应的数值模拟[J]. 太赫兹科学与电子信息学报, 2018, 16(1): 158-163.

Sun P, Li M, Yang Q X, et al. Numerical simulation of the accumulative photo-thermal effect in silicon under illumination with sequential laser pulses[J]. Journal of Terahertz Science and Electronic Information Technology, 2018, 16(1): 158-163.

[19] Chari V D. Sharma D V S G K, Prasad P S R, et al. Dependence of thermal conductivity in micro to nano silica[J]. Bulletin of Materials Science, 2013, 36(4): 517-520.

[20] 李志明, 聂劲松, 胡瑜泽, 等. 高频飞秒激光对硅材料烧蚀的热积累效应[J]. 激光与红外, 2017, 47(4): 410-415.

Li Z M, Nie J S, Hu Y Z, et al. Heat accumulation effects on the ablation of silicon with high frequency femtosecond laser[J]. Laser & Infrared, 2017, 47(4): 410-415.

[21] 赵凯峰, 程广贵, 张忠强, 等. 熔融硅在水平管道凝固过程的数值分析[J]. 热加工工艺, 2017, 46(9): 93-96.

Zhao K F, Cheng G G, Zhang Z Q, et al. Numerical simulation of solidification process of molten silicon in horizontal tube[J]. Hot Working Technology, 2017, 46(9): 93-96.

[22] 沈中华, 倪晓武, 陆建. 激光对半导体材料热作用的理论计算[J]. 光电子·激光, 1998, 9(4): 344-346.

Shen Z H, Ni X W, Lu J. Theoretical calculation for thermal effect of the semiconductors induced by the laser pulse[J]. Journal of Optoelectronics·Laser, 1998, 9(4): 344-346.

[23] 于天彪, 孙佳钰, 王航, 等. 温度场模拟激光熔覆TC11钛合金工艺参数的选择[J]. 激光与红外, 2017, 47(3): 284-290.

Yu T B, Sun J Y, Wang H, et al. Parameter selection of laser cladding TC11 titanium alloy simulated by temperature field[J]. Laser & Infrared, 2017, 47(3): 284-290.

[24] 陶春华.

金属粉末激光熔覆成形的基础实验与模拟[D].

大连: 大连理工大学,

2008:

29-

30.

Tao CH.

Basic experiment and simulation on laser cladding forming of metal powder[D].

Dalian: Dalian University of Technology,

2008:

29-

30.

[25] 张庆茂, 刘文今, 杨森, 等. 送粉式激光熔覆稀释率的分析模型及其影响因素[J]. 钢铁研究学报, 2002, 14(1): 11-15.

Zhang Q M, Liu W J, Yang S, et al. Analysis model of dilution and related factor in process of powder feeding laser cladding[J]. Journal of Iron and Steel Research, 2002, 14(1): 11-15.

[26] Hong J, Wang W, Shi B, et al. Screen-printed Si paste for localized B doping in a back surface field[J]. Proceedings of the IEEE, 2015, 36(1): 8-10.

下载: 1188次

下载: 1188次