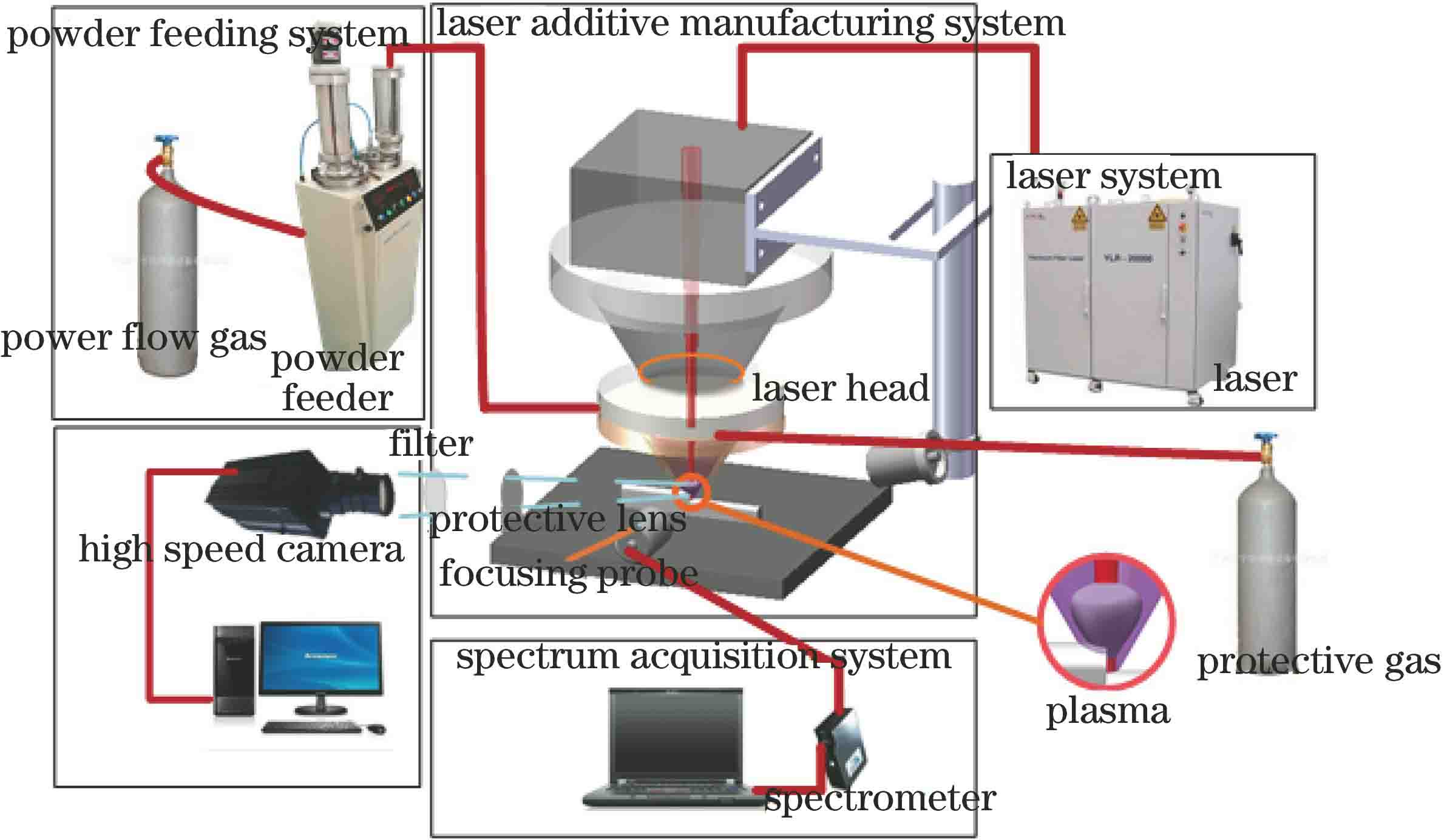

陶瓷激光增材制造等离子体特征与成形缺陷的相关性研究  下载: 999次

下载: 999次

刘安丽, 隋长有, 李发智, 张屹. 陶瓷激光增材制造等离子体特征与成形缺陷的相关性研究[J]. 中国激光, 2020, 47(6): 0602005.

Liu Anli, Sui Changyou, Li Fazhi, Zhang Yi. Correlation Between Plasma Characteristics and Forming Defects During Laser Additive Manufacturing of Ceramics[J]. Chinese Journal of Lasers, 2020, 47(6): 0602005.

[1] Li P, Li J L, Dong H G, et al. Metallurgical and mechanical properties of continuous drive friction welded copper/alumina dissimilar joints[J]. Materials & Design, 2017, 127: 311-319.

[2] Sapozhnikov S B, Kudryavtsev O A, Dolganina N. Experimental and numerical estimation of strength and fragmentation of different porosity alumina ceramics[J]. Materials & Design, 2015, 88: 1042-1048.

[3] Denry I, Holloway J. Ceramics fordental applications: a review[J]. Materials, 2010, 3(1): 351-368.

[4] Ashley S. Rapid prototyping systems[J]. Mechanical Engineering, 1991, 113(4): 34-43.

[6] Zocca A, Colombo P, Gomes C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities[J]. Journal of the American Ceramic Society, 2015, 98(7): 1983-2001.

[7] 信纪军, 方超, 杨武雄, 等. IC10单晶高温合金激光焊裂纹及显微组织的研究[J]. 中国激光, 2018, 45(8): 0802002.

[8] 李俐群, 孟圣昊, 彭进. 铝合金激光焊接熔池中气泡运动与气孔相关性分析[J]. 焊接学报, 2018, 39(6): 1-6.

Li L Q, Meng S H, Peng J. Analysis of correlation between bubble motion and weld porosity in laser welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2018, 39(6): 1-6.

[9] Yap C Y, Chua C K, Dong Z L, et al. Review of selective laser melting: materials and applications[J]. Applied Physics Reviews, 2015, 2(4): 041101.

[10] Fan Z Q, Lu M Y, Huang H. Selective laser melting of alumina: a single track study[J]. Ceramics International, 2018, 44(8): 9484-9493.

[11] Martin J H, Yahata B D, Hundley J M, et al. 3D printing of high-strength aluminium alloys[J]. Nature, 2017, 549(7672): 365-369.

[12] 陈静, 林鑫, 王涛, 等. 316L不锈钢激光快速成形过程中熔覆层的热裂机理[J]. 稀有金属材料与工程, 2003, 32(3): 183-186.

Chen J, Lin X, Wang T, et al. The hot cracking mechanism of 316L stainless steel cladding in rapid laser forming process[J]. Rare Metal Materials and Engineering, 2003, 32(3): 183-186.

[13] Zhou X, Li K, Zhang D D, et al. Textures formed in a CoCrMo alloy by selective laser melting[J]. Journal of Alloys and Compounds, 2015, 631: 153-164.

[14] 刘佳, 李忠, 石岩, 等. 光丝距对激光-电弧复合焊接熔池表面流动的影响[J]. 中国激光, 2018, 45(10): 1002004.

[15] 王军. 铝合金光纤激光及其复合焊接的等离子体行为与工艺研究[D]. 武汉: 华中科技大学, 2012: 57- 110.

WangJ. Study on the technology and plasma behaviour during the fiber laser and laser hybrid welding of aluminum alloy[D]. Wuhan: Huazhong University of Science and Technology, 2012: 57- 110.

[16] 王旭友, 孙谦, 王威, 等. 激光焊接中的等离子体变化规律及气孔缺陷快速测试方法: 检测信号整体分析方法[J]. 焊接学报, 2016, 37(3): 45-48.

Wang X Y, Sun Q, Wang W, et al. Study on the changing ruler of plasma in laser welding and the quick testing method of blowhole defects: integral analysis method for signals detection[J]. Transactions of the China Welding Institution, 2016, 37(3): 45-48.

[17] Harooni M, Carlson B, Kovacevic R. Detection of defects in laser welding of AZ31B magnesium alloy in zero-gap lap joint configuration by a real-time spectroscopic analysis[J]. Optics and Lasers in Engineering, 2014, 56: 54-66.

[18] ChenB, Yao YZ, Tan CW, et al. Investigation of the correlation between plasma electron temperature and quality of laser additive manufacturing process[M] ∥Chen S, Zhang Y, Feng Z. Transactions on Intelligent Welding Manufacturing. Singapore: Springer Singapore, 2017: 60- 74.

[19] Shaikh N M, Rashid B, Hafeez S, et al. Measurement of electron density and temperature of a laser-induced zinc plasma[J]. Journal of Physics D: Applied Physics, 2006, 39(7): 1384-1391.

[20] Cowpe J S, Pilkington R D, Astin J S, et al. The effect of ambient pressure on laser-induced silicon plasma temperature, density and morphology[J]. Journal of Physics D: Applied Physics, 2009, 42(16): 165202.

[21] Abdellatif G, Imam H. A study of the laser plasma parameters at different laser wavelengths[J]. Spectrochimica Acta Part B: Atomic Spectroscopy, 2002, 57(7): 1155-1165.

[22] Lu C, Lin Q D, Li B, et al. Effect of powder feeding rate on heat and mass transfer behaviors during filler powder laser welding[J]. Optics & Laser Technology, 2019, 120: 105711.

刘安丽, 隋长有, 李发智, 张屹. 陶瓷激光增材制造等离子体特征与成形缺陷的相关性研究[J]. 中国激光, 2020, 47(6): 0602005. Liu Anli, Sui Changyou, Li Fazhi, Zhang Yi. Correlation Between Plasma Characteristics and Forming Defects During Laser Additive Manufacturing of Ceramics[J]. Chinese Journal of Lasers, 2020, 47(6): 0602005.