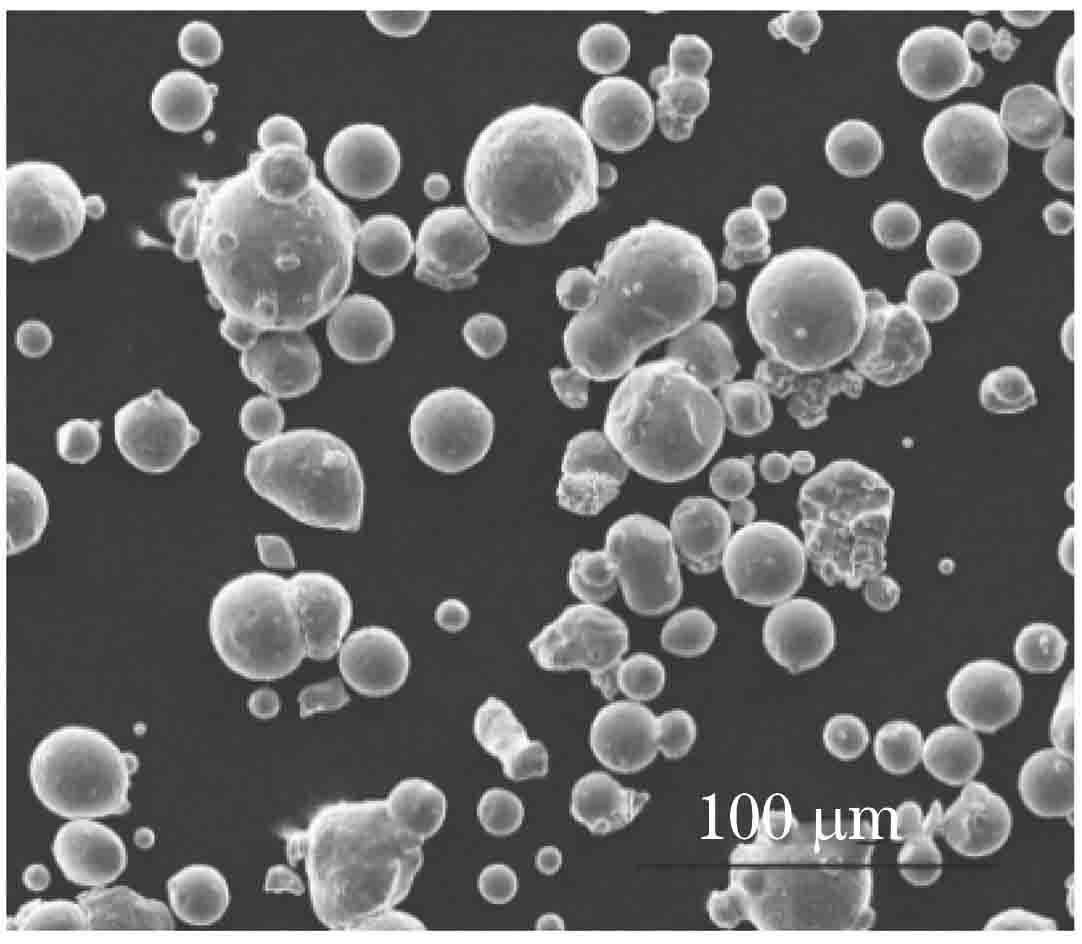

离焦量对3D打印18Ni-300马氏体时效钢组织和力学性能的影响  下载: 1030次

下载: 1030次

张佳琪, 王敏杰, 刘建业, 牛留辉, 王金海, 伊明扬. 离焦量对3D打印18Ni-300马氏体时效钢组织和力学性能的影响[J]. 中国激光, 2020, 47(5): 0502004.

Jiaqi Zhang, Minjie Wang, Jianye Liu, Liuhui Niu, Jinhai Wang, Mingyang Yi. Influence of Defocusing Distance on Microstructure and Mechanical Properties of 3D-Printed 18Ni-300 Maraging Steel[J]. Chinese Journal of Lasers, 2020, 47(5): 0502004.

[1] 张晓雅, 李现兵, 谈震, 等. 激光选区熔化水雾化Cu-10Sn合金粉末成形件的微观组织结构及力学性能研究[J]. 中国激光, 2018, 45(10): 1002009.

[2] Read N, Wang W, Essa K, et al. Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development[J]. Materials & Design, 2015, 65: 417-424.

[3] Abele E, Kniepkamp M. Analysis and optimisation of vertical surface roughness in micro selective laser melting[J]. Surface Topography: Metrology and Properties, 2015, 3(3): 034007.

[4] 高飘, 魏恺文, 喻寒琛, 等. 分层厚度对选区激光熔化成形Ti-5Al-2.5Sn合金组织与性能的影响规律[J]. 金属学报, 2018, 54(7): 999-1009.

Gao P, Wei K W, Yu H C, et al. Influence of layer thickness on microstructure and mechanical properties of selective laser melted Ti-5Al-2.5Sn alloy[J]. Acta Metallurgica Sinica, 2018, 54(7): 999-1009.

[5] Guo Y L, Jia L N, Kong B, et al. Single track and single layer formation in selective laser melting of niobium solid solution alloy[J]. Chinese Journal of Aeronautics, 2018, 31(4): 860-866.

[6] DemtröderW. Optics of Gaussian beams[M] ∥Laser Spectroscopy. Berlin, Heidelberg: Springer Berlin Heidelberg, 2014: 421- 429.

[7] Bean G E, Witkin D B. McLouth T D, et al. Effect of laser focus shift on surface quality and density of Inconel 718 parts produced via selective laser melting[J]. Additive Manufacturing, 2018, 22: 207-215.

[8] Metelkova J, Kinds Y, Kempen K, et al. On the influence of laser defocusing in selective laser melting of 316L[J]. Additive Manufacturing, 2018, 23: 161-169.

[9] Yao Y Z, Huang Y H, Chen B, et al. Influence of processing parameters and heat treatment on the mechanical properties of 18Ni300 manufactured by laser based directed energy deposition[J]. Optics & Laser Technology, 2018, 105: 171-179.

[10] Yin S, Chen C Y, Yan X C, et al. The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel[J]. Additive Manufacturing, 2018, 22: 592-600.

[11] McLouth T D, Bean G E, Witkin D B, et al. The effect of laser focus shift on microstructural variation of Inconel 718 produced by selective laser melting[J]. Materials & Design, 2018, 149: 205-213.

[12] 麦淑珍, 杨永强, 王迪. 激光选区熔化成型NiCr合金曲面表面形貌及粗糙度变化规律研究[J]. 中国激光, 2015, 42(12): 1203004.

[13] Gu D D, Shen Y F. Effects of processing parameters on consolidation and microstructure of W-Cu components by DMLS[J]. Journal of Alloys and Compounds, 2009, 473(1/2): 107-115.

[14] Casati R, Lemke J, Tuissi A, et al. Aging behaviour and mechanical performance of 18-Ni300 steel processed by selective laser melting[J]. Metals, 2016, 6(9): 218.

[15] Asgari H, Mohammadi M. Microstructure and mechanical properties of stainless steel CX manufactured by direct metal laser sintering[J]. Materials Science and Engineering: A, 2018, 709: 82-89.

[16] Ma M M, Wang Z M, Gao M, et al. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel[J]. Journal of Materials Processing Technology, 2015, 215: 142-150.

[17] Wang D, Song C H, Yang Y Q, et al. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts[J]. Materials & Design, 2016, 100: 291-299.

[18] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2007: 164- 168.

Hu HQ. Principle of metal solidification [M]. Beijing: China Machine Press, 2007: 164- 168.

[19] 陈帅, 陶凤和, 贾长治. 选区激光熔化4Cr5MoSiV1模具钢显微组织及显微硬度研究[J]. 中国激光, 2019, 46(1): 0102007.

[20] Song B, Dong S J, Liu Q, et al. Vacuum heat treatment of iron parts produced by selective laser melting: microstructure, residual stress and tensile behavior[J]. Materials & Design, 2014, 54: 727-733.

[21] Song B, Dong S J, Zhang B C, et al. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V[J]. Materials & Design, 2012, 35: 120-125.

[22] KurzW, Fisher DJ. Fundamentals of solidification[M]. Zürich: Trans Tech Publications, 1986

[23] Zhong Y, Liu L F, Wikman S, et al. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting[J]. Journal of Nuclear Materials, 2016, 470: 170-178.

张佳琪, 王敏杰, 刘建业, 牛留辉, 王金海, 伊明扬. 离焦量对3D打印18Ni-300马氏体时效钢组织和力学性能的影响[J]. 中国激光, 2020, 47(5): 0502004. Jiaqi Zhang, Minjie Wang, Jianye Liu, Liuhui Niu, Jinhai Wang, Mingyang Yi. Influence of Defocusing Distance on Microstructure and Mechanical Properties of 3D-Printed 18Ni-300 Maraging Steel[J]. Chinese Journal of Lasers, 2020, 47(5): 0502004.