激光增材制造温度场检测分析与控制综述  下载: 1648次

下载: 1648次

解瑞东, 朱尽伟, 张航, 崔滨, 张连重, 李涤尘, 高峰. 激光增材制造温度场检测分析与控制综述[J]. 激光与光电子学进展, 2020, 57(5): 050003.

Ruidong Xie, Jinwei Zhu, Hang Zhang, Bin Cui, Lianzhong Zhang, Dichen Li, Feng Gao. Review of Detection, Analysis and Control of Temperature Field in Laser Additive Manufacturing[J]. Laser & Optoelectronics Progress, 2020, 57(5): 050003.

[1] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690-2698.

[2] Lu B H, Li D C, Tian X Y. Development trends in additive manufacturing and 3D printing[J]. Engineering, 2015, 1(1): 85-89.

[3] Lewandowski J J, Seifi M. Metal additive manufacturing: a review of mechanical properties[J]. Annual Review of Materials Research, 2016, 46(1): 151-186.

[4] Ngo T D, Kashani A, Imbalzano G, et al. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges[J]. Composites Part B: Engineering, 2018, 143: 172-196.

[5] Murr L E. A metallographic review of 3D printing/additive manufacturing of metal and alloy products and components[J]. Metallography, Microstructure, and Analysis, 2018, 7(2): 103-132.

[6] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[7] 李祚, 隋尚, 袁子豪, 等. 高沉积率激光熔覆沉积GH4169合金的微观组织与拉伸性能[J]. 中国激光, 2019, 46(1): 0102004.

[8] Cao L, Chen S Y, Wei M W, et al. Effect of laser energy density on defects behavior of direct laser depositing 24CrNiMo alloy steel[J]. Optics & Laser Technology, 2019, 111: 541-553.

[9] Liu QC, ElambasserilJ, Sun SJ, et al., 2014, 891/892: 1519- 1524.

[10] Gong H J, Rafi K, Gu H F, et al. Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting[J]. Materials & Design, 2015, 86: 545-554.

[11] Xie R D, Li D C, Cui B, et al. A defects detection method based on infrared scanning in laser metal deposition process[J]. Rapid Prototyping Journal, 2018, 24(6): 945-954.

[12] 孙洪吉, 韦靖, 郑兆宏, 等. 激光工艺参数对激光熔化沉积纯钛样品残余应力的影响[J]. 中国激光, 2019, 46(3): 0302014.

[13] Carslaw HS, Jaeger JC. Conduction of heat in solids[M]. 2nd ed. Oxford: Clarendon Press, 1986.

[14] 李雅莉. 选区激光熔化AlSi10Mg温度场及应力场数值模拟研究[D]. 南京: 南京航空航天大学, 2015.

Li YL. Numerical investigation on temperature field and stress field during selective laser melting of AlSi10Mg[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015.

[15] Zhang Z D, Huang Y Z, Rani Kasinathan A, et al. 3-Dimensional heat transfer modeling for laser powder-bed fusion additive manufacturing with volumetric heat sources based on varied thermal conductivity and absorptivity[J]. Optics & Laser Technology, 2019, 109: 297-312.

[16] Arisoy Y M, Criales L E, Özel T. Modeling and simulation of thermal field and solidification in laser powder bed fusion of nickel alloy IN625[J]. Optics & Laser Technology, 2019, 109: 278-292.

[17] Schänzel M, Shakirov D, Ilin A, et al. Coupled thermo-mechanical process simulation method for selective laser melting considering phase transformation steels[J]. Computers & Mathematics With Applications, 2019, 78(7): 2230-2246.

[18] Panda B K, Sahoo S. Thermo-mechanical modeling and validation of stress field during laser powder bed fusion of AlSi10Mg built part[J]. Results in Physics, 2019, 12: 1372-1381.

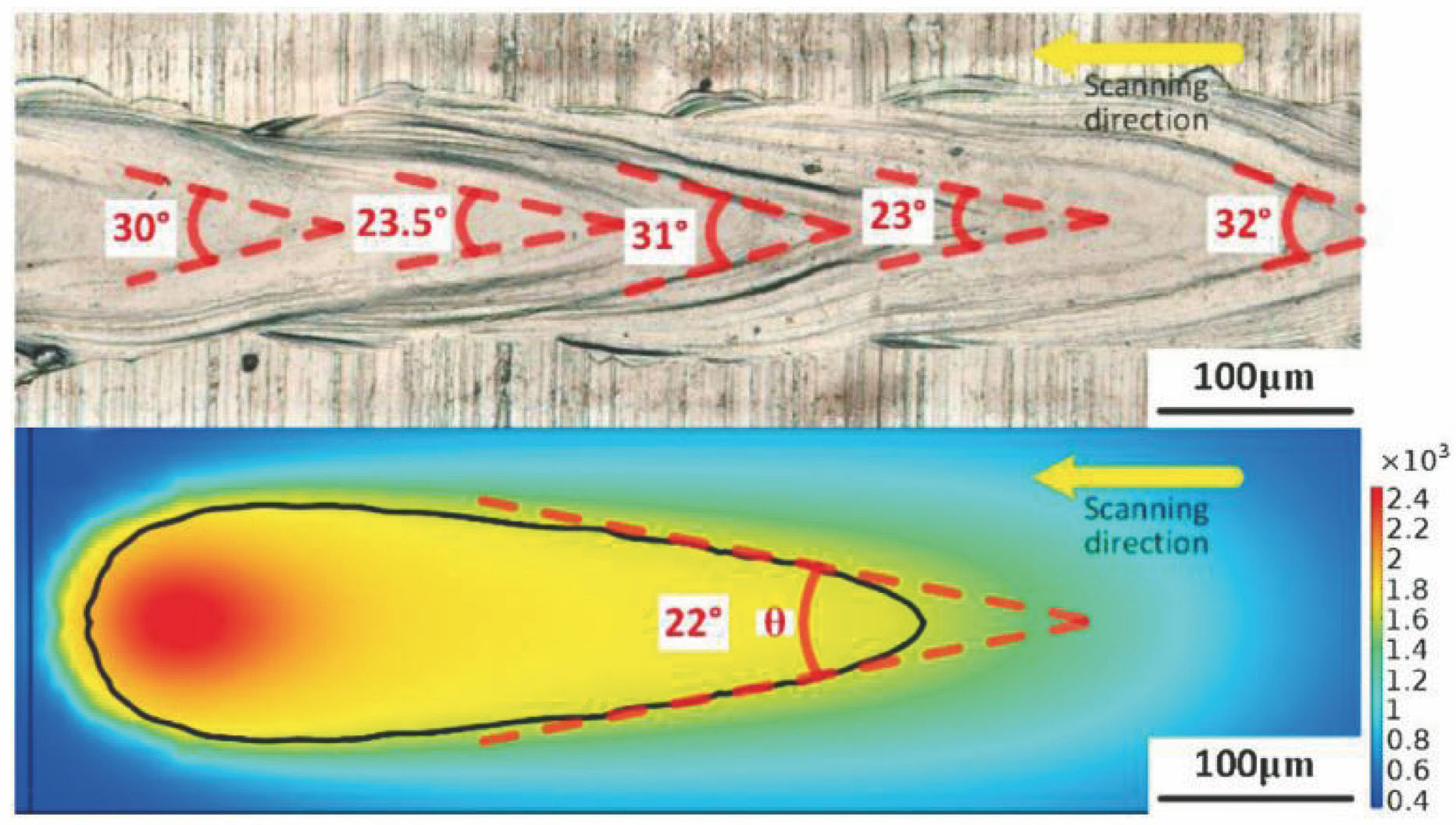

[19] Du Y, You X Y, Qiao F B, et al. A model for predicting the temperature field during selective laser melting[J]. Results in Physics, 2019, 12: 52-60.

[20] Yin J, Peng G Y, Chen C P, et al. Thermal behavior and grain growth orientation during selective laser melting of Ti-6Al-4V alloy[J]. Journal of Materials Processing Technology, 2018, 260: 57-65.

[21] 王亚晨. 激光熔覆温度场模拟及激光扫描顺序方法研究[D]. 乌鲁木齐: 新疆大学, 2018

Wang YC. Simulation of temperature field in laser cladding and study of laser scanning sequence method[D]. Urumqi: Xinjiang University, 2018.

[22] Zhang D Y, Feng Z, Wang C J, et al. Modeling of temperature field evolution during multilayered direct laser metal deposition[J]. Journal of Thermal Spray Technology, 2017, 26(5): 831-845.

[23] Gan Z T, Liu H, Li S X, et al. Modeling of thermal behavior and mass transport in multi-layer laser additive manufacturing of Ni-based alloy on cast iron[J]. International Journal of Heat and Mass Transfer, 2017, 111: 709-722.

[24] Gan Z T, Yu G, He X L, et al. Numerical simulation of thermal behavior and multicomponent mass transfer in direct laser deposition of co-base alloy on steel[J]. International Journal of Heat and Mass Transfer, 2017, 104: 28-38.

[25] Duan W, Yin Y J, Zhou J X. Temperature field simulations during selective laser melting process based on fully threaded tree[J]. China Foundry, 2017, 14(5): 405-411.

[26] Wei P, Wei Z Y, Chen Z, et al. Thermal behavior in single track during selective laser melting of AlSi10Mg powder[J]. Applied Physics A, 2017, 123(9): 604.

[27] 雷剑波. 基于CCD的激光再制造熔池温度场检测研究[D]. 天津: 天津工业大学, 2007.

Lei JB. Detection of laser remanufacturing molten pool temperature field based on CCD[D]. Tianjin: Tianjin Polytechnic University, 2007.

[28] Hudson RD. Infrared system engineering[M]. New York: John Wiley & Sons, Inc., 1969.

[29] Hooper P A. Melt pool temperature and cooling rates in laser powder bed fusion[J]. Additive Manufacturing, 2018, 22: 548-559.

[30] Lane B, Whitenton E, Moylan S. Multiple sensor detection of process phenomena in laser powder bed fusion[J]. Proceedings of SPIE, 2016, 9861: 986104.

[31] Lane B, Moylan S, Whitenton E P, et al. Thermographic measurements of the commercial laser powder bed fusion process at NIST[J]. Rapid Prototyping Journal, 2016, 22(5): 778-787.

[32] Marshall G J, Young W J, Thompson S M, et al. Understanding the microstructure formation of Ti-6Al-4V during direct laser deposition via in-situ thermal monitoring[J]. JOM, 2016, 68(3): 778-790.

[33] Li S M, Xiao H, Liu K Y, et al. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed- and continuous-wave laser additive manufacturing: a comparative study[J]. Materials & Design, 2017, 119: 351-360.

[34] de Baere D, Devesse W, de Pauw B, et al. Spectroscopic monitoring and melt pool temperature estimation during the laser metal deposition process[J]. Journal of Laser Applications, 2016, 28(2): 022303.

[35] 袁钰函. 基于彩色CCD的激光熔池的温度场检测与研究[D]. 合肥: 合肥工业大学, 2018.

Yuan YH. Detection of laser molten pool temperature field based on CCD[D]. Hefei: Hefei University of Technology, 2018.

[36] 钦兰云, 徐丽丽, 杨光, 等. 钛合金激光沉积制造热累积与熔池形貌演化[J]. 稀有金属材料与工程, 2017, 46(9): 2645-2650.

Qin L Y, Xu L L, Yang G, et al. Correlations of thermal accumulation and melt pool geometry during laser deposition manufacturing of titanium alloy[J]. Rare Metal Materials and Engineering, 2017, 46(9): 2645-2650.

[38] 朱进前, 凌泽民, 杜发瑞, 等. 激光熔丝增材制造温度场的红外热像监测[J]. 红外与激光工程, 2018, 47(6): 0604002.

[39] 徐红祥. 选择性激光熔融成型层温度特性的研究[D]. 合肥: 合肥工业大学, 2018.

Xu HX. Study on temperature characteristics of selective laser melting forming layer[D]. Hefei: Hefei University of Technology, 2018.

[40] Segerstark A, Andersson J, Svensson L E. Evaluation of a temperature measurement method developed for laser metal deposition[J]. Science and Technology of Welding and Joining, 2016, 22(1): 1-6.

[41] Petrat T, Winterkorn R, Graf B, et al. Build-up strategies for temperature control using laser metal deposition for additive manufacturing[J]. Welding in the World, 2018, 62(5): 1073-1081.

[42] Devesse W, de Baere D, Hinderdael M, et al. Hardware-in-the-loop control of additive manufacturing processes using temperature feedback[J]. Journal of Laser Applications, 2016, 28(2): 022302.

[43] 张荣华, 宋立军. 激光增材制造熔池温度实时监测与控制[J]. 应用激光, 2018, 38(1): 13-18.

[44] 孙华杰. 基于彩色CCD的激光熔覆熔池温度闭环控制研究[D]. 苏州: 苏州大学, 2018.

Sun HJ. Research on close-loop control of molten pool temperature during laser cladding process based on color CCD[D]. Suzhou: Soochow University, 2018.

[45] 沈初杰, 赵宗仁, 袁自钧, 等. 基于温度控制的激光熔覆成形工艺研究[J]. 合肥工业大学学报(自然科学版), 2017, 40(5): 660-664.

Shen C J, Zhao Z R, Yuan Z J, et al. Research on laser cladding forming technology based on temperature control[J]. Journal of Hefei University of Technology(Natural Science), 2017, 40(5): 660-664.

[46] Song L, Bagavath-Singh V, Dutta B, et al. Control of melt pool temperature and deposition height during direct metal deposition process[J]. The International Journal of Advanced Manufacturing Technology, 2012, 58: 247-256.

[47] Miyagi M, Tsukamoto T, Kawanaka H. Adaptive shape control of laser-deposited metal structures by adjusting weld pool size[J]. Journal of Laser Applications, 2014, 26(3): 032003.

[48] Craeghs T, Bechmann F, Berumen S, et al. Feedback control of layerwise laser melting using optical sensors[J]. Physics Procedia, 2010, 5: 505-514.

[50] Tang L, Landers R G. Layer-to-layer height control for laser metal deposition process[J]. Journal of Manufacturing Science and Engineering, 2011, 133(2): 021009.

[51] Tang L, Landers R G. Melt pool temperature control for laser metal deposition processes: part I: online temperature control[J]. Journal of Manufacturing Science and Engineering, 2010, 132(1): 011010.

[52] Maly M, Höller C, Skalon M, et al. Effect of process parameters and high-temperature preheating on residual stress and relative density of Ti6Al4V processed by selective laser melting[J]. Materials, 2019, 12(6): 930.

[53] Sato Y, Tsukamoto M, Shobu T, et al. Preheat effect on titanium plate fabricated by sputter-free selective laser melting in vacuum[J]. Applied Physics A, 2018, 124(4): 288.

[54] Ali H, Ma L, Ghadbeigi H, et al. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of selective laser melted Ti6Al4V[J]. Materials Science and Engineering: A, 2017, 695: 211-220.

[55] Mertens R, Dadbakhsh S, Van Humbeeck J, et al. Application of base plate preheating during selective laser melting[J]. Procedia CIRP, 2018, 74: 5-11.

[56] 卞宏友, 翟泉星, 曲伸, 等. 基体预热下激光沉积修复GH4169合金温度场和应力场演变[J]. 应用激光, 2017, 37(3): 327-332.

[57] Ding C G, Cui X, Jiao J Q, et al. Effects of substrate preheating temperatures on the microstructure, properties, and residual stress of 12CrNi2 prepared by laser cladding deposition technique[J]. Materials, 2018, 11(12): 2401.

[58] Fang J X, Li S B, Dong S Y, et al. Effects of phase transition temperature and preheating on residual stress in multi-pass & multi-layer laser metal deposition[J]. Journal of Alloys and Compounds, 2019, 792: 928-937.

[59] Xu J J, Lin X, Guo P F, et al. The effect of preheating on microstructure and mechanical properties of laser solid forming IN-738LC alloy[J]. Materials Science and Engineering: A, 2017, 691: 71-80.

[60] Buchbinder D, Meiners W, Pirch N, et al. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting[J]. Journal of Laser Applications, 2014, 26(1): 012004.

[61] Zhang K, Wang S J, Liu W J, et al. Effects of substrate preheating on the thin-wall part built by laser metal deposition shaping[J]. Applied Surface Science, 2014, 317: 839-855.

[62] Kempen K, Vrancken B, Buls S, et al. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating[J]. Journal of Manufacturing Science and Engineering, 2014, 136(6): 061026.

[63] Fallah V, Alimardani M, Corbin S F, et al. Impact of localized surface preheating on the microstructure and crack formation in laser direct deposition of Stellite 1 on AISI 4340 steel[J]. Applied Surface Science, 2010, 257(5): 1716-1723.

解瑞东, 朱尽伟, 张航, 崔滨, 张连重, 李涤尘, 高峰. 激光增材制造温度场检测分析与控制综述[J]. 激光与光电子学进展, 2020, 57(5): 050003. Ruidong Xie, Jinwei Zhu, Hang Zhang, Bin Cui, Lianzhong Zhang, Dichen Li, Feng Gao. Review of Detection, Analysis and Control of Temperature Field in Laser Additive Manufacturing[J]. Laser & Optoelectronics Progress, 2020, 57(5): 050003.