非熔透激光搭接焊SUS304奥氏体不锈钢无焊缝侧变形机理  下载: 904次

下载: 904次

刘恩泽, 姚成武, 谢雨凌, 张旭东. 非熔透激光搭接焊SUS304奥氏体不锈钢无焊缝侧变形机理[J]. 中国激光, 2019, 46(4): 0402004.

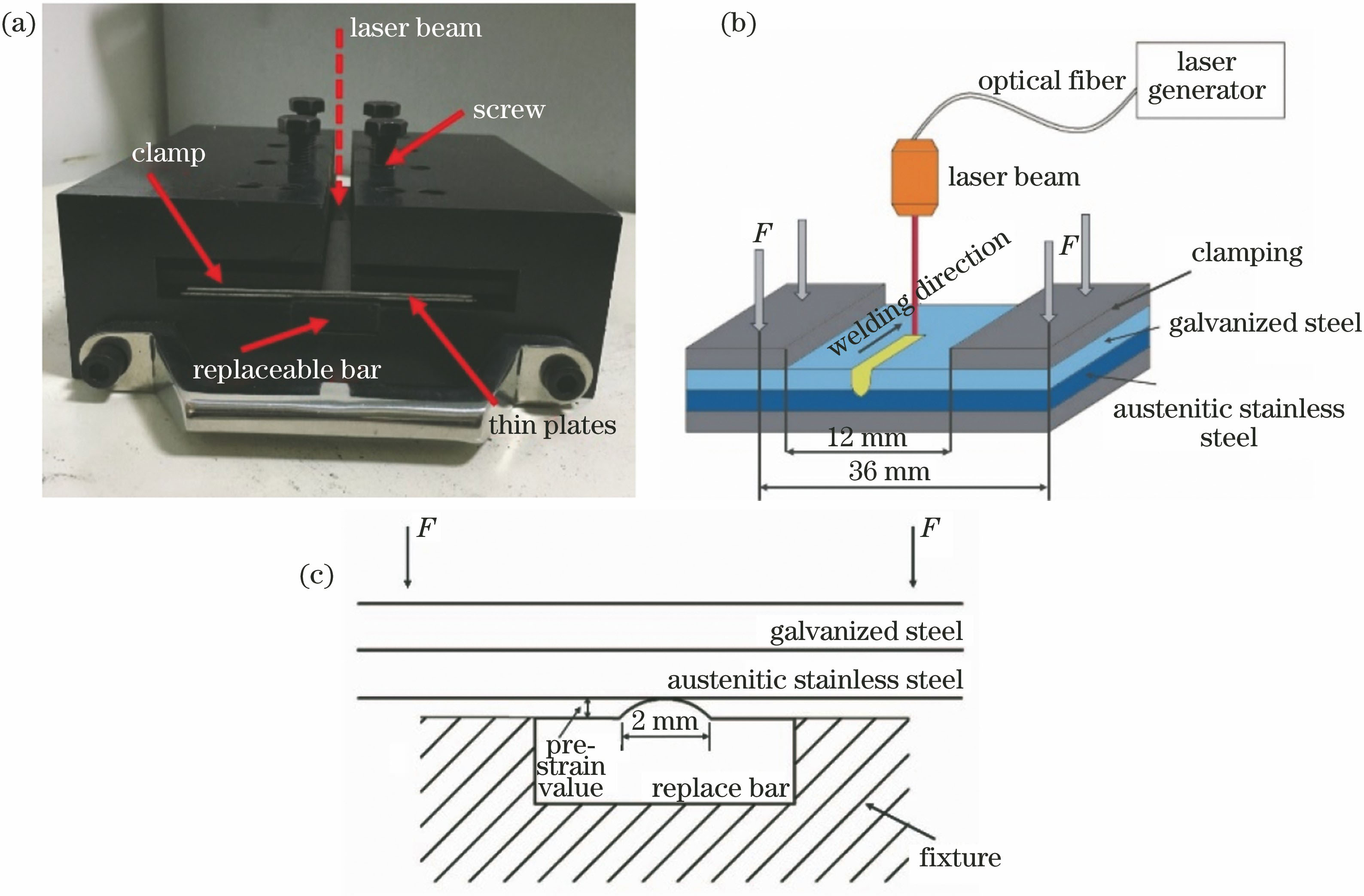

Enze Liu, Chengwu Yao, Yuling Xie, Xudong Zhang. Deformation Mechanism of SUS304 Austenitic Stainless Steel at Weldless Side in Partial Penetration Laser Welding[J]. Chinese Journal of Lasers, 2019, 46(4): 0402004.

[1] 郑锐, 林建平, 吴倩倩, 等. 结构胶胶接汽车车身金属接头抗环境腐蚀性能研究进展[J]. 材料工程, 2015, 43(3): 98-105.

[2] 游敏, 郑小玲. 连接结构分析[M]. 武汉: 华中科技大学出版社, 2004.

YouM, Zheng XL. Connection structure analysis[M]. Wuhan: Huazhong University of Science and Technology Press, 2004.

[3] 马海全, 王倩妮, 钱雷, 等. 胶接结构破坏模式及失效机理[J]. 失效分析与预防, 2012, 7(3): 162-166.

[4] Wang H Z, Nakanishi M, Kawahito Y. Effects of welding speed on absorption rate in partial and full penetration welding of stainless steel with high brightness and high power laser[J]. Journal of Materials Processing Technology, 2017, 249: 193-201.

[6] 梁行, 阚盈, 姜云禄, 等. 不锈钢薄板激光搭接焊接头的力学性能[J]. 中国激光, 2018, 45(6): 0602001.

[7] 曾强, 朱绍维, 付正鸿. 不同焊接工艺对SUS301L-MT不锈钢接头组织和力学性能的影响[J]. 激光与光电子学进展, 2018, 55(3): 031405.

[8] 周学凯, 米高阳, 刘森, 等. 304不锈钢/T2紫铜超薄板激光搭接焊[J]. 中国激光, 2017, 44(8): 0802006.

[10] 侯志刚. 薄板结构焊接变形的预测与控制[D]. 武汉: 华中科技大学, 2005.

Hou ZG. Prediction and control of welding deformation of sheet structures[D]. Wuhan: Huazhong University of Science and Technology, 2005.

[11] 孟祥海, 李孟星, 吴丽学, 等. 汽车镀锌钢板焊接缺陷分析及对策[J]. 铸造技术, 2018, 39(3): 625-627.

[14] 姬大鹏. 镀锌钢板点焊工艺及焊接缺陷研究[D]. 长沙: 湖南大学, 2012.

Ji DP. Spot welding process of galvanized steel & failure of spot welding research[D]. Changsha: Hunan University, 2012.

[17] Chakraborty S S, Racherla V, Nath A K. Thermo-mechanical finite element study on deformation mechanics during radial scan line laser forming of a bowl shaped surface out of a thin sheet[J]. Journal of Manufacturing Processes, 2018, 31: 593-604.

[20] 孙向伟, 殷咸青, 王江超, 等. 采用三维光学测量技术对薄板焊接失稳变形的分析[J]. 焊接学报, 2013, 34(6): 109-112, 118.

[21] 刘佳. 轨道客车用SUS301L奥氏体不锈钢激光叠焊技术研究[D]. 长春: 长春理工大学, 2012.

LiuJ. Research on laser lap welding technology of SUS301L austenitic stainless steel for railway vehicles[D]. Changchun: Changchun University of Science and Technology, 2012.

[22] 方洪渊. 焊接结构学[M]. 北京: 机械工业出版社, 2008.

Fang HY. Welding structure[M]. Beijing: China Machine Press, 2008.

刘恩泽, 姚成武, 谢雨凌, 张旭东. 非熔透激光搭接焊SUS304奥氏体不锈钢无焊缝侧变形机理[J]. 中国激光, 2019, 46(4): 0402004. Enze Liu, Chengwu Yao, Yuling Xie, Xudong Zhang. Deformation Mechanism of SUS304 Austenitic Stainless Steel at Weldless Side in Partial Penetration Laser Welding[J]. Chinese Journal of Lasers, 2019, 46(4): 0402004.