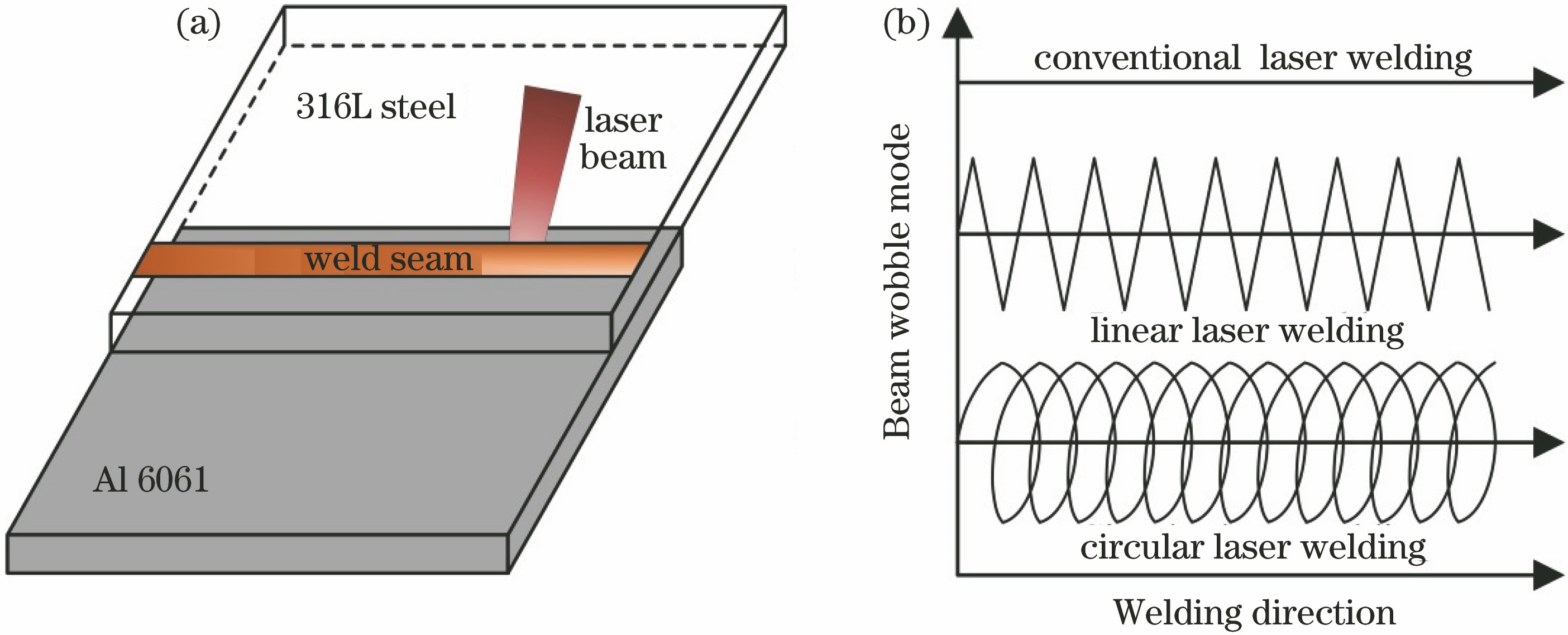

激光摆动模式对铝/钢焊接接头成形特征及组织、强度的影响  下载: 1203次

下载: 1203次

李军兆, 刘一搏, 孙清洁, 陶玉洁, 张清华, 靳鹏, 冯吉才. 激光摆动模式对铝/钢焊接接头成形特征及组织、强度的影响[J]. 中国激光, 2020, 47(4): 0402010.

Li Junzhao, Liu Yibo, Sun Qingjie, Tao Yujie, Zhang Qinghua, Jin Peng, Feng Jicai. Effects of Laser Beam Wobble on Weld Formation Characteristics, Microstructure, and Strength of Aluminum Alloy/Steel Joints[J]. Chinese Journal of Lasers, 2020, 47(4): 0402010.

[1] Cao R, Yu G, Chen J H, et al. Cold metal transfer joining aluminum alloys-to-galvanized mild steel[J]. Journal of Materials Processing Technology, 2013, 213(10): 1753-1763.

[2] 李杰, 黄健康, 靳全胜. 铝/钢异种金属熔钎焊方法研究现状[J]. 电焊机, 2018, 48(1): 109-114.

Li J, Huang J K, Jin Q S. Research status of welding-brazing of aluminum/steel dissimilar metals[J]. Electric Welding Machine, 2018, 48(1): 109-114.

[3] 黄健康, 王梓懿, 刘宁, 等. 金属镀层对铝/钢激光熔钎焊接头组织与性能的影响[J]. 材料工程, 2018, 46(5): 99-105.

Huang J K, Wang Z Y, Liu N, et al. Effect of metal coating on microstructure and properties of aluminum/steel laser welding-brazing joint[J]. Journal of Materials Engineering, 2018, 46(5): 99-105.

[4] Qin G L, Ao Z Y, Chen Y, et al. Formability behavior of Al/steel MIG arc brazed-fusion welded joint[J]. Journal of Materials Processing Technology, 2019, 273: 116255.

[5] 崔凌越, 米高阳, 胡席远, 等. 基于CuSi3焊丝的激光熔钎焊钢/铝异种金属工艺分析[J]. 焊接学报, 2018, 39(9): 6-12.

Cui L Y, Mi G Y, Hu X Y, et al. Microstructure and mechanical properties of laser welding-brazed aluminum alloy to steel with CuSi3 filler metal[J]. Transactions of the China Welding Institution, 2018, 39(9): 6-12.

[6] 黄永宪, 黄体方, 万龙, 等. 铝/钢异种材料搅拌摩擦焊研究进展[J]. 精密成形工程, 2018, 10(1): 23-30.

Huang Y X, Huang T F, Wan L, et al. Research progress of dissimilar friction stir welding between aluminium and steel[J]. Journal of Netshape Forming Engineering, 2018, 10(1): 23-30.

[7] 马雨晴, 王红阳, 刘黎明. 基于Ni中间层的铝合金与高强钢激光诱导TIG复合焊接[J]. 中国激光, 2019, 46(8): 0802002.

[8] Mortazavi SN, MarashiP, PouranvariM, et al. and low carbon steel[J]. Advanced Materials Research, 2011, 264/265: 384- 389.

[9] Yan F, Fang X, Chen L, et al. Microstructure evolution and phase transition at the interface of steel/Al dissimilar alloys during Nd∶YAG laser welding[J]. Optics & Laser Technology, 2018, 108: 193-201.

[10] Xia H B, Zhao X Y, Tan C W, et al. Effect of Si content on the interfacial reactions in laser welded-brazed Al/steel dissimilar butted joint[J]. Journal of Materials Processing Technology, 2018, 258: 9-21.

[11] Long J Q, Huang W H, Xiang J W, et al. Parameter optimization of laser welding of steel to Al with pre-placed metal powders using the Taguchi-response surface method[J]. Optics & Laser Technology, 2018, 108: 97-106.

[12] Yan F, Wang X W, Chai F, et al. Improvement of microstructure and performance for steel/Al welds produced by magnetic field assisted laser welding[J]. Optics & Laser Technology, 2019, 113: 164-170.

[13] Cui L, Chen B X, Chen L, et al. Dual beam laser keyhole welding of steel/aluminum lapped joints[J]. Journal of Materials Processing Technology, 2018, 256: 87-97.

[14] Yuan R, Deng S J, Cui H C, et al. Interface characterization and mechanical properties of dual beam laser welding-brazing Al/steel dissimilar metals[J]. Journal of Manufacturing Processes, 2019, 40: 37-45.

[15] Shah L H, Khodabakhshi F, Gerlich A. Effect of beam wobbling on laser welding of aluminum and magnesium alloy with nickel interlayer[J]. Journal of Manufacturing Processes, 2019, 37: 212-219.

[16] Fetzer F, Sommer M, Weber R, et al. Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi[J]. Optics and Lasers in Engineering, 2018, 108: 68-77.

[17] Dimatteo V, Ascari A, Fortunato A. Continuous laser welding with spatial beam oscillation of dissimilar thin sheet materials (Al-Cu and Cu-Al): process optimization and characterization[J]. Journal of Manufacturing Processes, 2019, 44: 158-165.

李军兆, 刘一搏, 孙清洁, 陶玉洁, 张清华, 靳鹏, 冯吉才. 激光摆动模式对铝/钢焊接接头成形特征及组织、强度的影响[J]. 中国激光, 2020, 47(4): 0402010. Li Junzhao, Liu Yibo, Sun Qingjie, Tao Yujie, Zhang Qinghua, Jin Peng, Feng Jicai. Effects of Laser Beam Wobble on Weld Formation Characteristics, Microstructure, and Strength of Aluminum Alloy/Steel Joints[J]. Chinese Journal of Lasers, 2020, 47(4): 0402010.