黑体涂层光谱发射率特性研究  下载: 688次

下载: 688次

0 引 言

黑体辐射源是用于校准辐射温度计以及红外热像仪等的标准仪器[1-2],而红外光谱发射率作为黑体最重要的指标之一,定义为相同温度和波长下物体的辐射能力和理想黑体在相同温度和波长下的比值[3]。实际黑体的发射率与黑体表面的微结构和涂层材料的发射率密切相关,即在特定的结构下,黑体的发射率受其表面涂层辐射特性的影响[4]。涂层的发射率不是涂层固有的性质,与诸多因素有关,比如涂层的厚度、涂层表面粗糙度、所需波长以及喷涂工艺等[5]。近年来,气象卫星配备了黑体辐射源,用于在轨实时定标。对星载黑体而言,空间带电粒子对黑体表面涂层的损伤不可忽视,涂层受空间照射影响,发射率特性会发生变化[6],易对高精度定标产生影响。因此,黑体涂层发射率特性的研究对实现高精度的红外遥感定标显得尤为重要。

目前,德国联邦物理技术研究院(PTB)测量了Nextel 811-21在120 ℃的温度下,波长范围从5~20 µm,在不同的观察角度下的光谱发射率。发现观察角度在30°范围内,光谱发射率几乎不变,当与法向夹角由30°变化到70°时,发射率由0.9717降低到0.9120。又对比测量了Herberts 1534在120 ℃的大气温度和25 ℃的真空温度下,波长范围为5.7~18.2 µm的定向光谱发射率,在与法向夹角为10°观察角度下,得到两种测量环境下的光谱发射率大小几乎相同[7]。中国计量科学研究院(NIM)宋健等人通过控制环境辐射的方法测量了Nextel 811-21、JSC-3和Pyromark 1200三种高发射率涂层在8~14 µm的法向发射率,结果分别为0.964、0.979和0.901[8]。

文中基于中国计量科学研究院发射率测量装置,探究了涂层光谱发射率的影响因素,包括测量环境、厚度、角度,并分析了光谱发射率特性。利用地面模拟空间辐射环境照射样品涂层,对比了黑体涂层辐照前后光谱发射率的变化。

1 发射率测量原理及装置

1.1 测量原理

一个理想黑体辐射源,其光谱辐射亮度可以由普朗克黑体辐射定律计算得到:

式中:c1=3.7418

温度大于绝对零度的物体,其表面会辐射能量,还会反射来自环境的能量,物体表面出射的总能量为:

式中:ε为物体表面光谱发射率;L(T)为温度为T时理想黑体的光谱辐亮度;Lbg为环境辐射亮度。

当在样品涂层前放置一块高发射率的辐射板时,辐射板成为环境辐射的一部分[9],则光谱仪测量的样品信号S为:

式中:r为光谱响应系数;L为样品光谱辐亮度;Lbg为辐射板照射时总的环境辐射信号;Le为仪器自身信号。

当两个温度不同的辐射板分别照射待测样品时,可得到光谱仪测量信号S1、S2为:

式中:L1、L2 分别为常温和高温辐射板照射时样品的光谱辐亮度;Lbg1、Lbg2分别为常温和高温辐射板照射时的总环境辐射信号。

同样的,当常温和高温辐射板分别照射黑体时,可得到黑体光谱信号Sbb1、Sbb2:

式中:Lbb1、Lbb2 分别为常温和高温辐射板照射时的黑体的光谱辐亮度;Lbg1、Lbg2分别为常温和高温辐射板照射时的总环境辐射信号。

根据公式(4)~(7),设

当辐射板分别为常温和高温时,则总的环境辐射信号分别为:

式中:F为辐射板相对待测样品的角系数;Ln和Lh分别是常温和高温辐射板辐射亮度;Lex为辐射板以外的环境辐射[10]。

联立公式(8)~(10),由于S是光谱仪测量的信号,所以Q可看作常数,可得样品发射率为:

式中:Lbbh和Lbbn分别为测量黑体时高温和常温辐射板的辐亮度。

1.2 测量装置

中国计量科学研究院搭建的基于控制环境辐射发射比法的发射率测量装置如图1所示[8,11],它由红外傅里叶光谱仪、高温辐射板(一般设置85 ℃)、常温辐射板(一般设置21 ℃)、高精度测温仪等组成。通过步进电机的转动使常温和高温辐射板在样品表面交替,红外傅里叶光谱仪测量样品辐射和反射环境的能量变化,便可通过样品的温度变化和光谱信号计算出光谱发射率。装置具有较好的重复性和稳定性,发射率测量误差为0.005[8]。

2 样品制备

采用直径为50 mm的高导热铝合金作为样品基材,在基材的侧面钻有一温度计小孔,便于温度的测量。采用重力式喷枪喷涂,将涂层材料均匀的喷涂在基材一侧的铝表面,如图2所示。

选取GR、Nextel 811-21、多壁碳纳米管(MWCNT)三种涂层材料制备黑体涂层,分别将其命名为GR涂层、Nextel 811-21涂层和Nextel 811-21+MWCNT涂层,图3为制备的样品涂层实物照片。

3 实验结果

3.1 涂层大气与真空光谱发射率对比

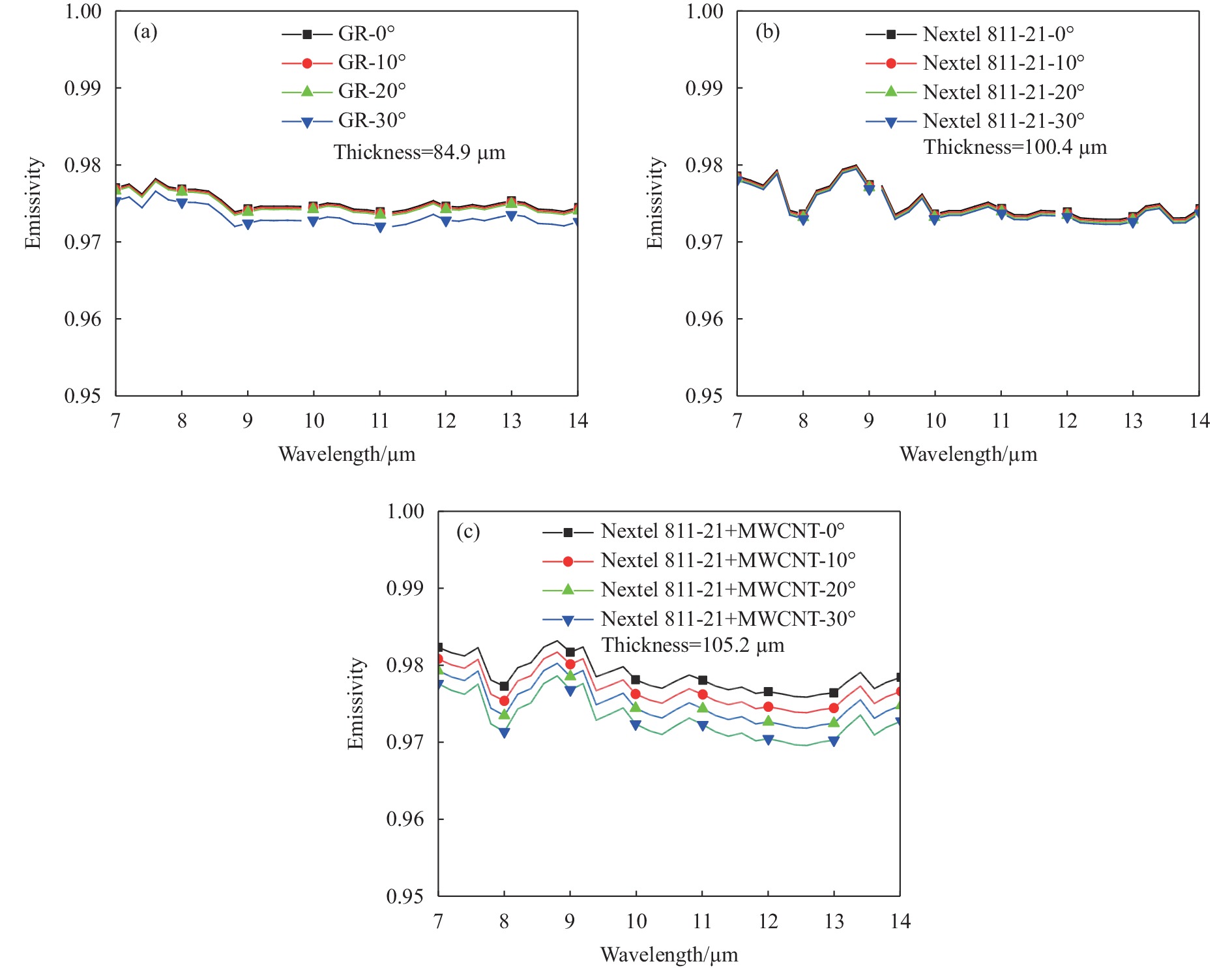

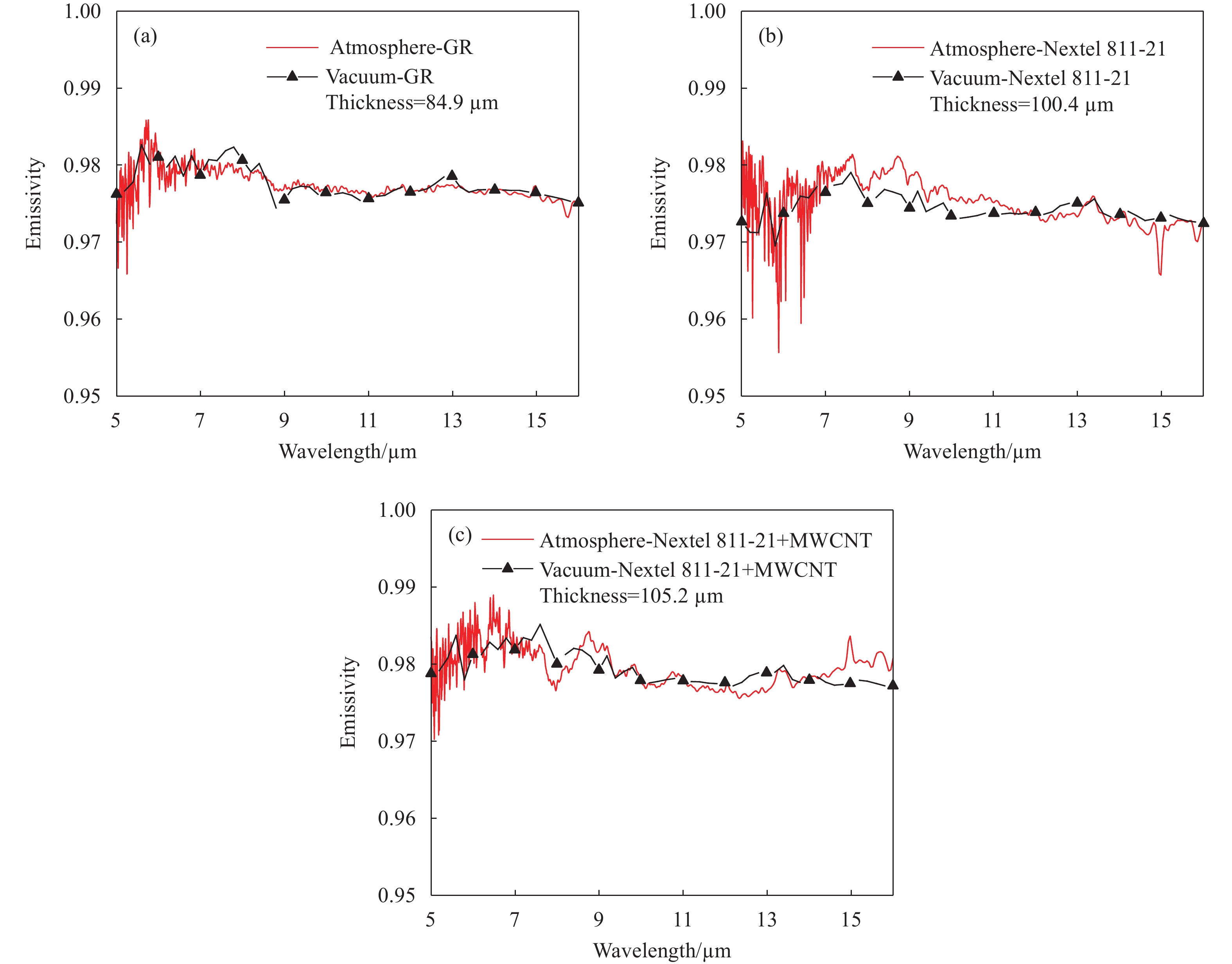

三种涂层在真空与大气下的法向室温光谱发射率如图4所示,涂层的真空发射率是在红外遥感亮度温度国家计量标准装置上测量的[12-13]。可看出三种涂层在大气下5~7 µm光谱发射率均出现较大抖动,原因在于涂层发出的红外辐射在到达光谱仪之前会经过一段空气,而空气中存在大量的二氧化碳(CO2)和水蒸气(H2O)等气体,涂层红外辐射经过这些气体时,在红外波段产生共振,会出现红外辐射选择性吸收,因此涂层的辐射能量到达光谱仪会降低,从而存在着大气吸收的影响。在真空下,探测器信噪比高,噪声小,MCT探测器可以测量较宽波段的光谱发射率,测量结果优于大气下,且15 µm处涂层光谱发射率无CO2吸收峰。对比三种涂层光谱发射率,由此可以看出在8~14 µm波段内,GR涂层波形较为平坦,而Nextel 811-21和Nextel 811-21+MWCNT有着较为明显的波峰波谷,且两种涂层光谱发射率波形一致,因碳纳米管具有较好地红外吸收性,添加在Nextel 811-21涂层材料中碳纳米管,对原有涂层的辐射特性有所增强[14]。

图 4. 三种涂层真空与大气光谱发射率对比

Fig. 4. Comparison of spectral emissivity between vacuum and atmosphere of three coatings

3.2 涂层厚度对涂层光谱发射率的影响

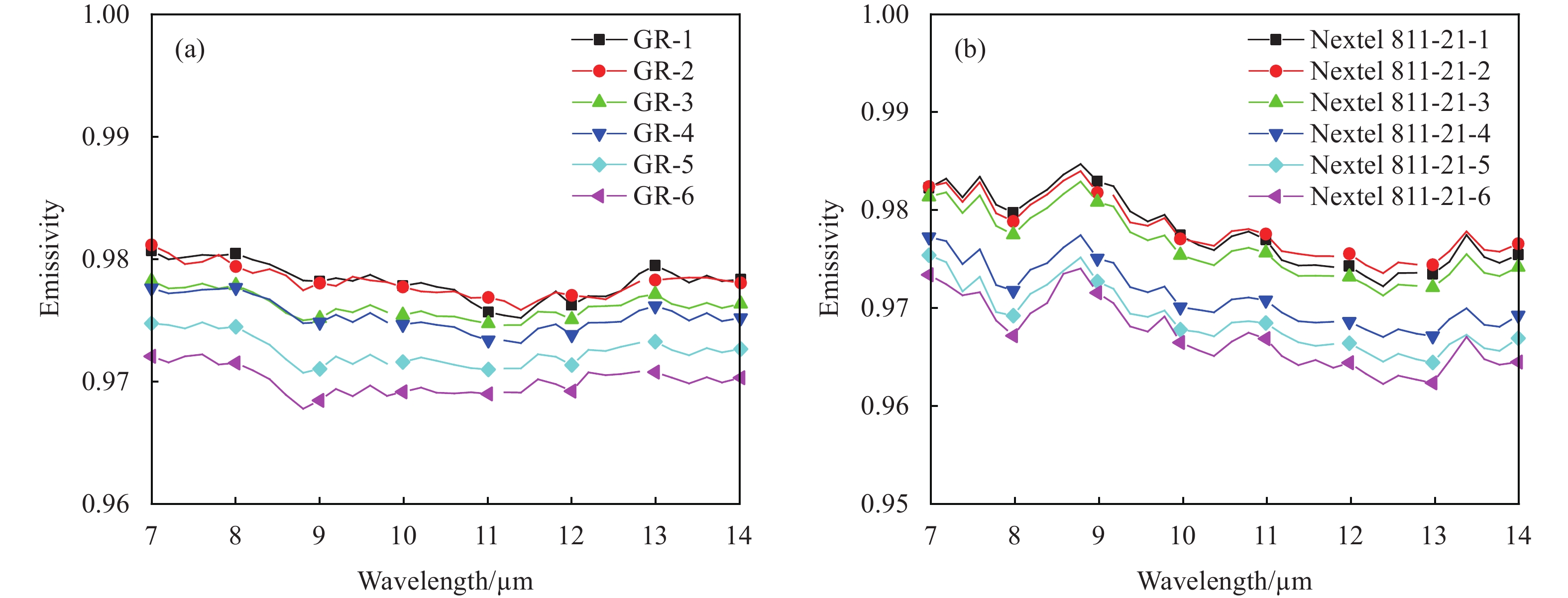

通过改变喷涂的次数制备不同厚度的GR和Nextel 811-21涂层,Nextel 811-21+MWCNT涂层连续多次喷涂,会使得碳纳米管在喷枪口部堆积,造成喷涂过程不连续,使得制备的涂层厚度、物相不均匀,影响涂层整体发射率的表现,不利于探究厚度对其发射率的影响。因此,重点分析GR和Nextel 811-21涂层厚度的影响。用表面轮廓仪测量涂层多处位置,取其平均值,对比不同厚度的涂层法向发射率变化,表1为涂层厚度及其发射率对照表。

表 1. Nextel 811-21与GR涂层厚度、发射率对照表

Table 1. Nextel 811-21 and GR coating thickness, emissivity comparison table

|

由表1和图5可以看出,GR和Nextel 811-21涂层在不同厚度下的光谱发射率具有相似特性,涂层较厚时,发射率偏低,涂层较薄时,发射率偏高。最大发射率差值相差0.01。当GR涂层厚度大于62 µm,Nextel 811-21涂层厚度增大到73 µm,涂层发射率会逐渐减小,但涂层发射率的变化,并不随着涂层厚度的变化呈现线性关系。即当厚度在某一小范围变化时,厚度的增加或减少,并不一定使得发射率变小或变大。由于人工制备涂层时并不能保证制备条件恒定不变,比如喷枪到样品表面的雾化距离、喷枪能否与样品表面保持垂直,这导致制备的样品涂层表面粗糙度往往有一定波动,而不同表面粗糙度的涂层对红外光捕获或共振吸收的能力不一样,从而影响了涂层的吸收率,可能会造成涂层发射率的不稳定。

图 5. 不同厚度的GR与Nextel 811-21涂层光谱发射率

Fig. 5. Spectral emissivity of GR and Nextel 811-21 coatings of different thickness

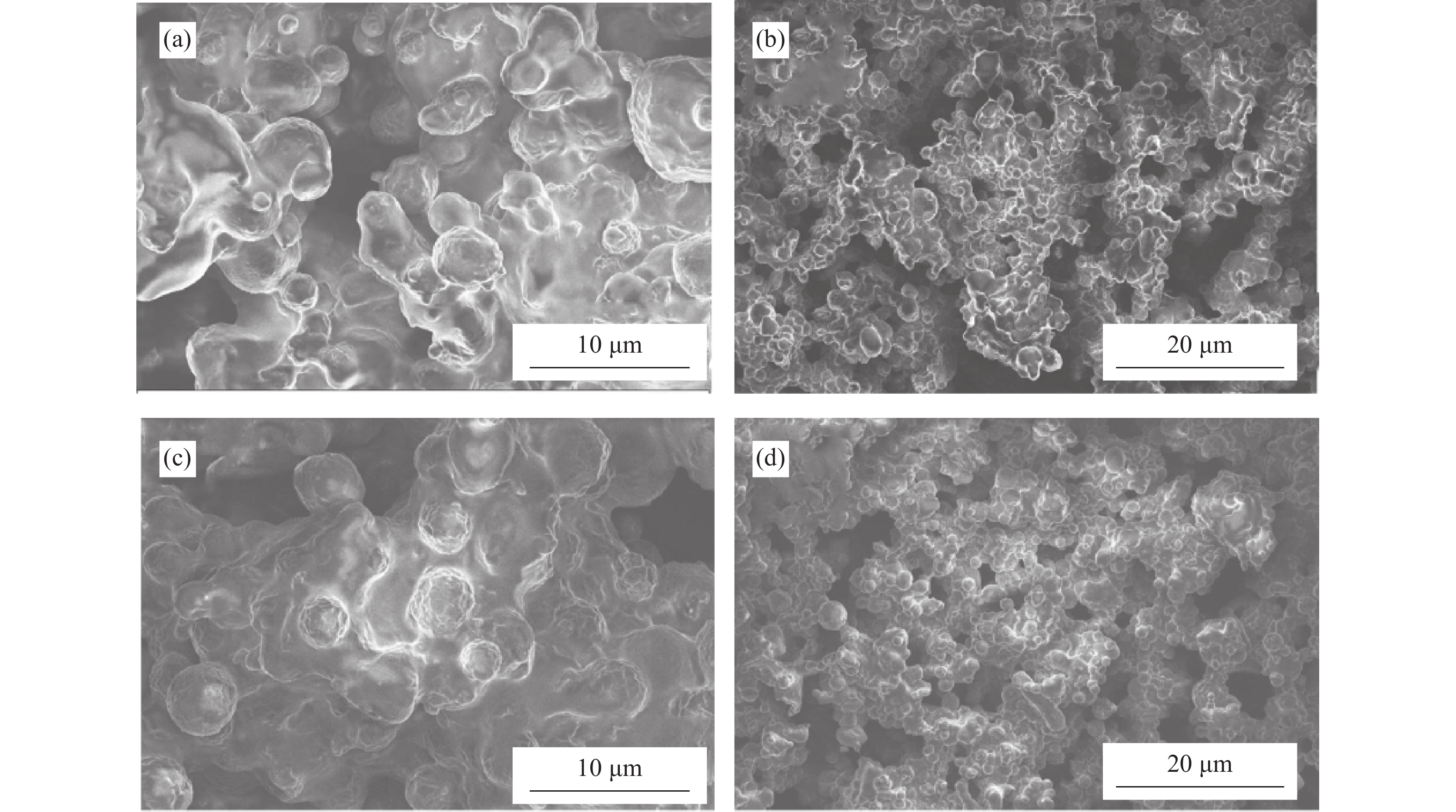

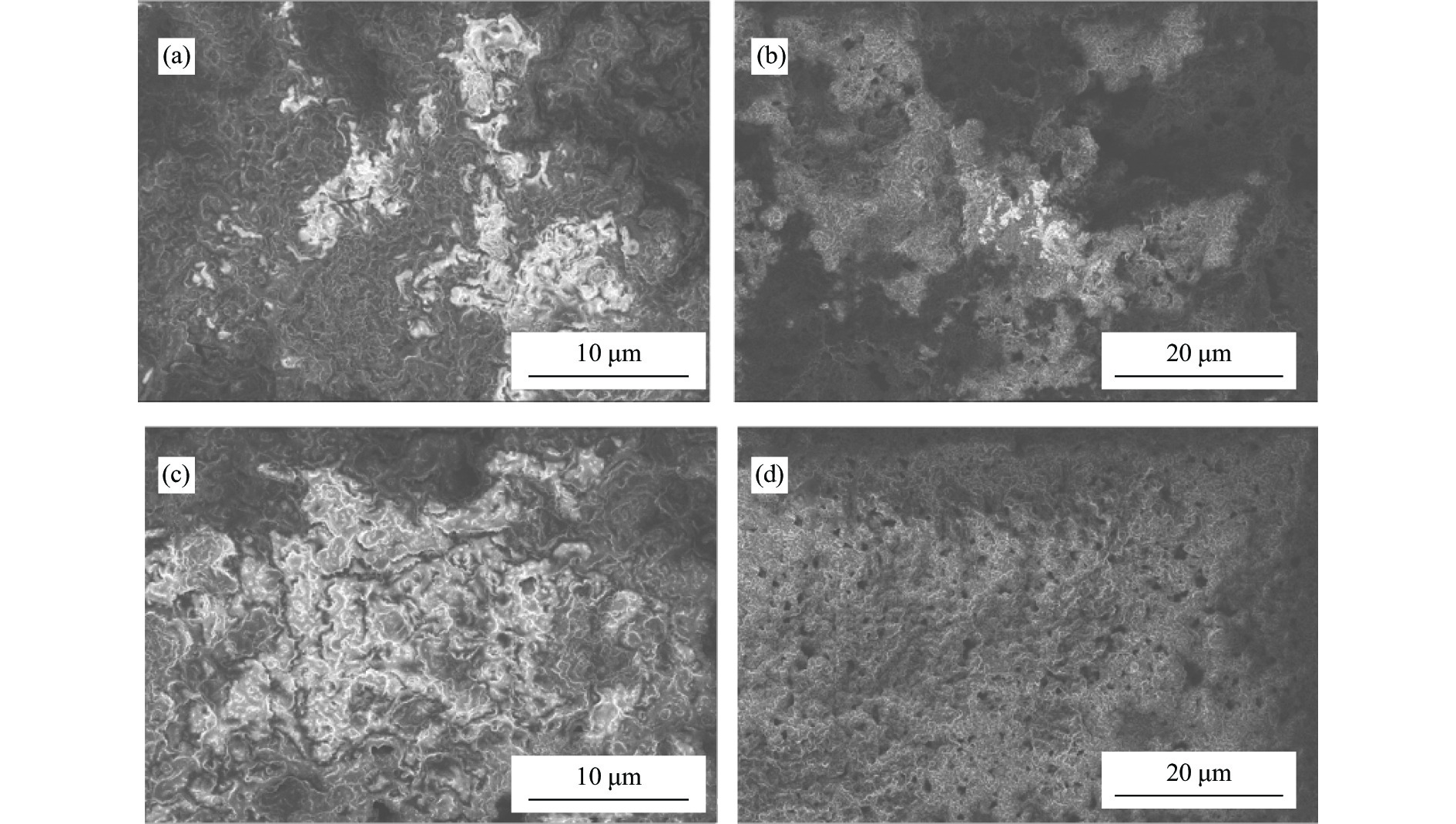

涂层的扫描电镜如图6和图7所示,从微观结构上可看出,涂层较薄时,涂层颗粒较细,分布均匀,表面呈多孔状,而随着涂层厚度增加,表面颗粒多呈团状,颗粒间相互粘连,孔隙较少。当涂层表面存在大量的多孔结构,孔隙从结构上讲如同一个开有小孔的空腔,这些多孔结构有大量的界面存在一定的曲率,可捕获电磁波,当入射辐射由小孔进入空腔后,在腔体表面上产生多次反射,每一次反射,辐射就被吸收一部分,最后只有极少量的辐射从孔中逸出,导致涂层具有较高的发射率。因此,当涂层较薄时,涂层表面孔隙数量较多,有利于提高涂层的发射率。

图 6. Nextel 811-21涂层扫描电镜对比图。 (a)和(b)是1000倍和200倍的薄涂层;(c)和(d)是1000倍和200倍的厚涂层

Fig. 6. SEM comparison of Nextel 811-21 coatings. (a) and (b) are 1000 × and 200 × thin coatings; (c) and (d) are 1000 × and 200 × thicker coatings

图 7. GR涂层扫描电镜对比图 。(a)和(b)是1000倍和200倍的薄涂层;(c)和(d)是1000倍和200倍的厚涂层

Fig. 7. SEM comparison of GR coatings. (a) and (b) are 1000 × and 200 × thin coatings; (c) and (d) are 1000 × and 200 × thicker coatings

实际上,对应用在黑体的涂层并不是越薄越好,过薄会造成基底裸露,即当电磁波入射到涂层表面时,会有部分电磁波穿过涂层,导致透过现象,会引入铝基底的辐射特性,使得涂层发射率降低;过厚,由于表面应力会造成黑漆的开裂脱落,都不具有实际应用意义,对黑体的辐射特性造成很大影响。

3.3 角度对涂层发射率影响

三种涂层在0°、10°、20°、30°测量角度的发射率如图8所示,可见高发射率黑体涂层在小角度变化范围内,发射率变化很小。当测量角度超过20°时,GR涂层发射率有略微的减小,但变化幅度很小。Nextel 811-21在30°变化范围内,发射率基本保持不变,这与德国联邦物理技术研究院测量结果一致[7],而Nextel 811-21+MWCNT涂层随着测量角度的变大,发射率会逐渐降低,与Nextel 811-21涂层相比,有着较大的不同。原因在于涂层表面存在多壁碳纳米管(MWCNT),会改变原有Nextel 811-21涂层表面形貌,使得Nextel 811-21+MWCNT涂层对发射角敏感。从图中可以看出,三种涂层发射率朝着较大角度降低是比较明显的。

3.4 空间辐照对涂层发射率特性的影响

空间环境中含极为丰富的粒子,长期暴露在空间辐射环境的黑体辐射面,易造成表面涂层发射率特性的变化。考虑到涂层厚度较薄时,辐射能量可能会入射到涂层的铝基底上,该实验选用厚度适中的涂层样品,分别是接近85 µm的GR涂层、100 µm的Nextel 811-21涂层和109 µm的Nextel 811-21+MWCNT涂层,利用地面模拟设备在真空度为1×10−4 Pa的环境下对涂层辐照,具体辐照数据如表2所示。

表 2. 空间辐照对照表

Table 2. Space irradiation comparison table

|

辐照后的涂层无起泡、裂纹、起皮、掉落等现象,但三种涂层的颜色均由原先的黑色变为灰黑色。随着辐照剂量增加,涂层颜色偏灰程度逐渐加深。为了分析辐照后的涂层发射率变化是否由测量误差引起的,将同批次同工艺且未辐照的留样涂层与用于辐照涂层在相同时间间隔对比测量,辐照前将留样涂层和待辐照涂层一起测量发射率,辐照后将留样涂层和已辐照涂层再次一起测量发射率。由表3可以看出,留样涂层两次测量的发射率变化量小于万分之三,证明测量装置具有较好稳定性。

表 3. 留样涂层发射率对照表

Table 3. Comparison table of emissivity of retained sample coatings

|

表4对比了涂层在辐照前后大气环境下的室温发射率,可看出,3 年总剂量辐照对所有涂层发射率几乎无影响,当空间辐照总剂量增加,GR涂层发射率会降低0.0004-0.0009,Nextel 811-21+MWCNT涂层发射率会降低0.0011-0.0021,而Nextel 811-21涂层发射率会增大0.0008-0.0017。可见,辐照后涂层发射率的变化量大于表3留样涂层数据变化量。因此,辐照后涂层发射率变化不是由测量误差引起的,辐照对涂层发射率变化较小,没有较为严重的影响。

表 4. 样品涂层辐照前后发射率对照表

Table 4. Comparison table of emissivity of sample coating before and after irradiation

|

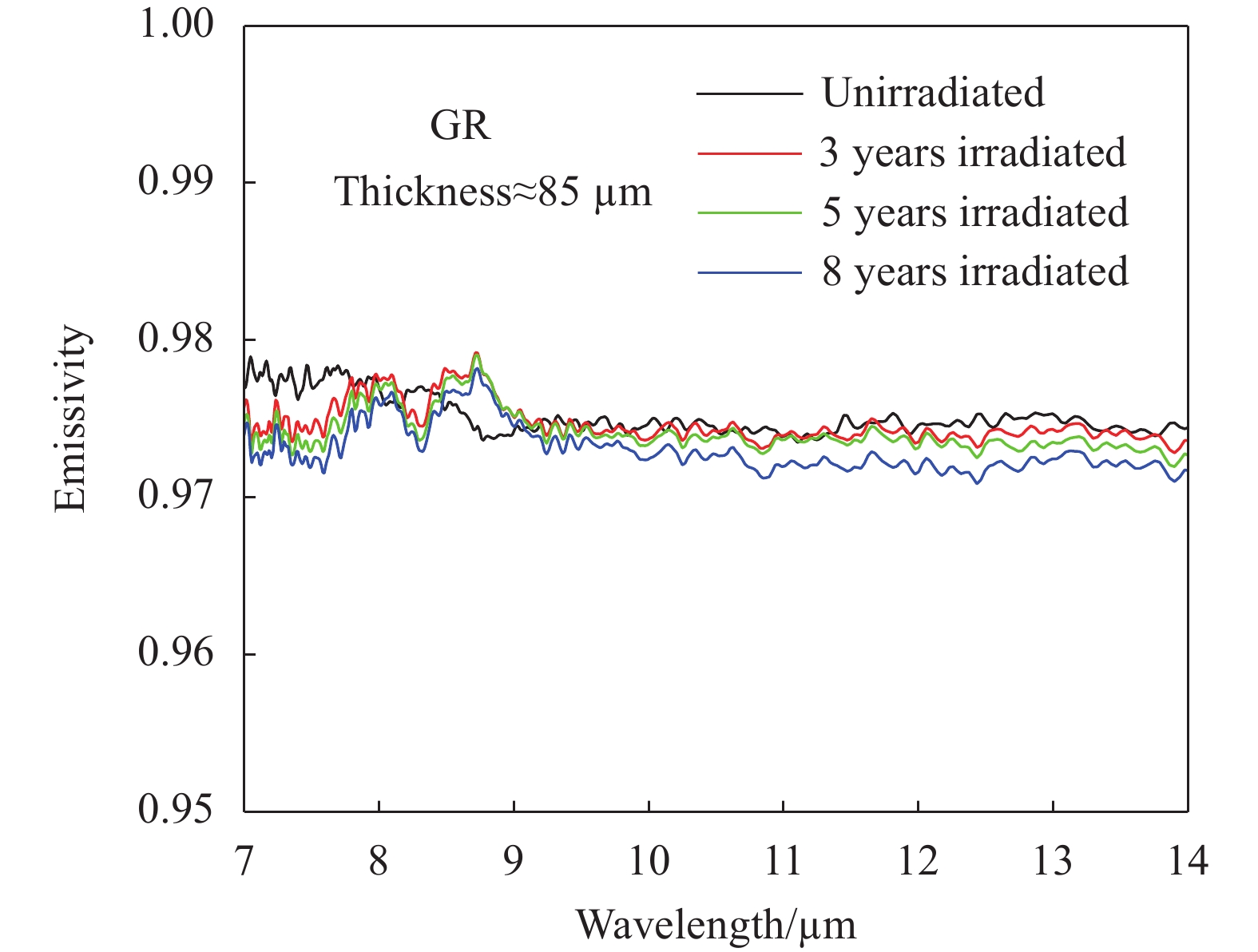

GR涂层空间辐照前后光谱发射率变化如图9所示,随着模拟辐照年份的增加,GR涂层受空间辐照的损伤会逐渐严重,涂层光谱发射率会减小。3年总剂量辐照对涂层发射率几乎无影响,10~14 µm处光谱发射率几乎重合,而5年和8年的总剂量辐照对涂层发射率会略微降低。辐照后的涂层光谱发射率都会在8~9 µm处出现波峰波谷的翻转。可见,当GR涂层与带电粒子相互作用时,会使涂层发射率特性发生退化。原因在于具有一定能量的带电粒子(如质子、电子)入射到涂层物质时,带电粒子与其路径上涂层的原子核或电子会发生库仑相互作用,从而把一部分动能转移给涂层物质的电子或原子核而逐渐损失能量,最终停止在该涂层物质中[15]。

图 9. GR涂层辐照前后光谱发射率对比

Fig. 9. Comparison of spectral emissivity of GR coatings before and after irradiation

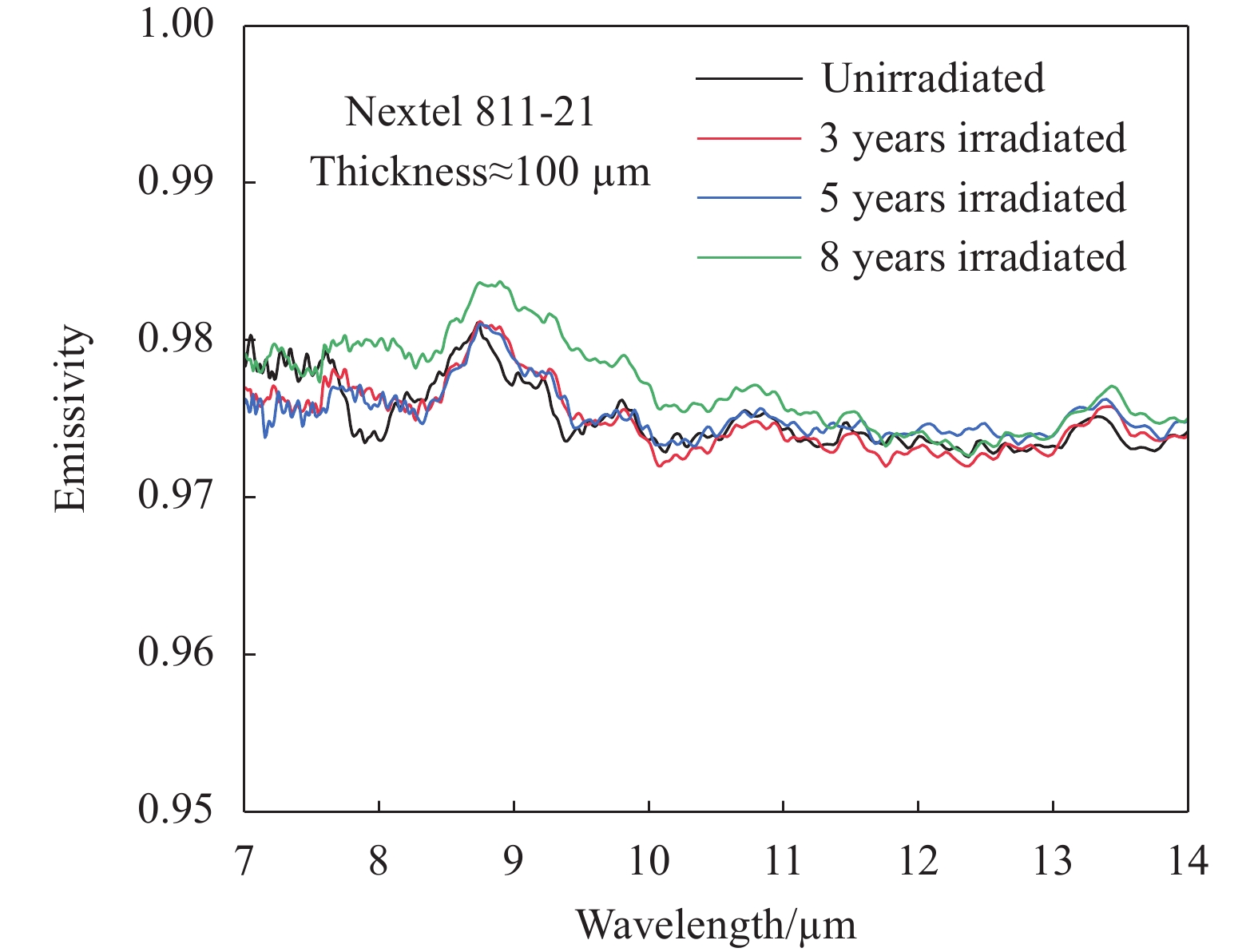

图10中,Nextel 811-21涂层随着辐照年份的增加,红外光谱发射率变化与GR涂层是相反的。3年辐照的影响不是很大,光谱发射率波形几乎重合,而5年和8年的辐照,发射率会略有变大。各阶段辐照的涂层,发射率波形具有相似性,在8~9 µm处,光谱发射率都会出现波峰波谷向长波偏移,10~14 µm处波形基本不变。

图 10. Nextel 811-21涂层辐照前后光谱发射率对比

Fig. 10. Comparison of spectral emissivity of Nextel 811-21 coatings before and after irradiation

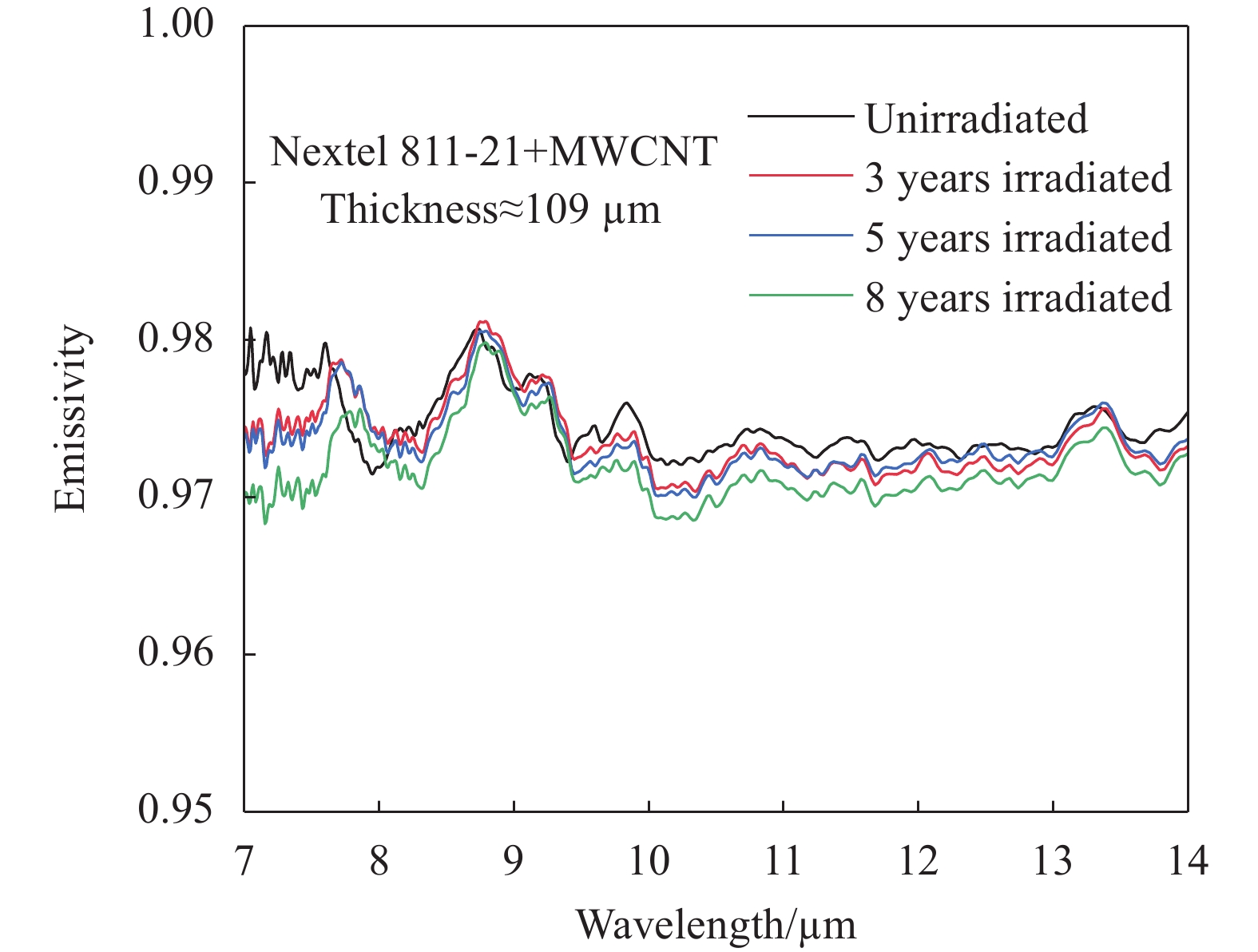

Nextel 811-21+MWCNT涂层被辐照的各阶段如图11所示,发射率性能衰减比GR涂层更为迅速。涂层发射率受模拟8年辐照剂量影响最大。由于涂层在空间暴露一定时期后,辐照环境对材料的损伤具有累积性特征,发射率特性会有不同程度的变化。对比辐照前后光谱发射率波形可看出,在8~9 µm处,会出现波峰波谷向长波移动,这和Nextel 811-21涂层辐照后变化相似。在10~14 µm波段内,光谱发射率波形保持不变。

图 11. Nextel 811-21+MWCNT涂层辐照前后光谱发射率比

Fig. 11. Comparison of spectral emissivity of Nextel 811- 21+MWCNT coatings before and after irradiation

4 结 论

黑体涂层光谱发射率受真空环境、测量角度、以及涂层厚度影响。从上述实验中可见,涂层真空下发射率与大气下相似,但测量结果优于大气下。当测量角度在30°内变化时,GR和Nextel 811-21涂层光谱发射率基本不变,仍然处于高发射率状态,而Nextel 811-21+MWCNT涂层随着测量角度的变大,发射率会降低。当GR和Nextel 811-21涂层较厚时,会导致涂层孔隙减少,造成发射率降低,不利于高精度红外遥感定标。

利用地面模拟设备对涂层辐照,辐照后涂层表面颜色由黑色变为灰黑色,但涂层未出现掉落、裂纹等裂纹现象,证明涂层具有一定的空间稳定性。辐照剂量最大时,GR涂层发射率减小0.0009,Nextel 811-21+MWCNT涂层发射率减小0.0021,Nextel 811-21涂层发射率增大0.0017,从实验结果可看出带电粒子对涂层发射率没有较为严重影响。所有辐照后的涂层10~14 µm处的光谱发射率波形变化平稳,无明显波动。涂层辐照实验为在轨运行的星载黑体寿命评估提供了数据支撑。

[1] Qian Jing, Sun Shengli, Yu Shengyun, , et al. Design of large size infrared radiant planar source[J]. Infrared and Laser Engineering, 2013, 42(1): 31-35.

[4] Niu Zhitian, Qi Hong, Hao Xiaopeng, , et al. Research on influence factors of spatial reference blackbody source emissivity[J]. Chinese Journal of Engineering Thermophysics, 2021, 42(9): 2442-2447.

[5] Song Xuyao, Dong Wei, Pan Yijie, , et al. The infrared spectral emissivity measurement of a graphite material in a high temperature range of 1 000-1 500 ℃ using integrated blackbody principle[J]. J Infrared Millim Waves, 2021, 40(2): 204-213.

[6] Ping Tuo, Zhou Ying, Yu Chengwu, , et al. Effect of simulated space radiation environments on properties of stray light coatings[J]. Surface Technology, 2020, 49(12): 30-37.

[7] Adibekyan A, Kononogova E, Monte C, , et al. High-accuracy emissivity data on the coatings Nextel 811-21, Herberts 1534, Aeroglaze Z306 and Acktar Fractal Black[J]. International Journal of Thermophysics, 2017, 38(6): 1-14.

[8] Song J, Hao X P, Yuan Z D, , et al. Research of ultra-black coating emissivity based on a controlling the surrounding radiation method[J]. International Journal of Thermophysics, 2018, 39(7): 1-10.

[14] Zhang H, Hao X, Su W, , et al. Strongly enhanced infrared emission of a black coating doped with multiwall carbon nanotubes[J]. Infrared Physics & Technology, 2021, 113: 103651.

[15] Zhao Chunqing, Ding Yigang, Liu Yuming, , et al. Performance degradation of antistatic thermal control coatings under proton and electron irradiation degradation of antistatic electrothermal coatings under proton and electron irradiation[J]. High Voltage Engineering, 2016, 42(5): 1442-1448.

Article Outline

丁经纬, 郝小鹏, 于坤, 宋健, 周晶晶. 黑体涂层光谱发射率特性研究[J]. 红外与激光工程, 2023, 52(10): 20230033. Jingwei Ding, Xiaopeng Hao, Kun Yu, Jian Song, Jingjing Zhou. Research on spectral emissivity characteristics of blackbody coatings[J]. Infrared and Laser Engineering, 2023, 52(10): 20230033.