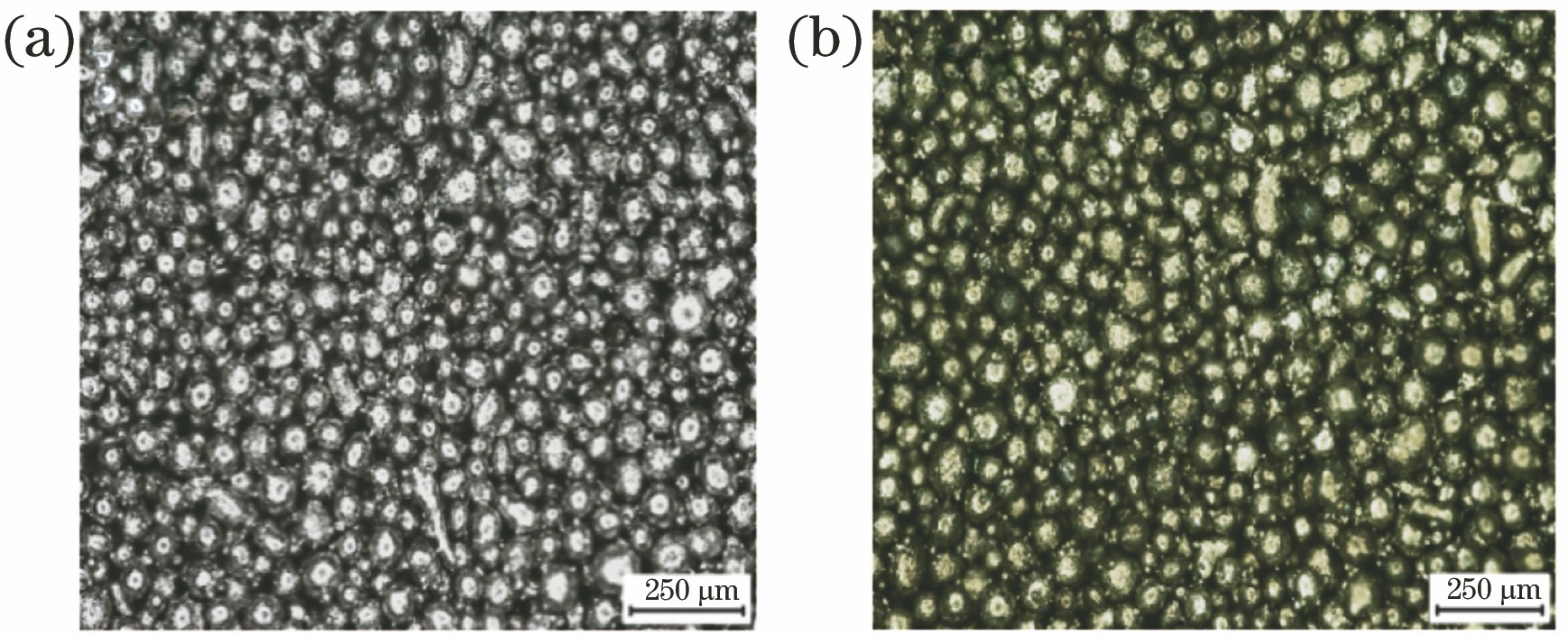

激光熔覆含氮奥氏体不锈钢层的组织与性能  下载: 980次

下载: 980次

宋勇, 朱伟, 李胜, 张聪, 邱长军. 激光熔覆含氮奥氏体不锈钢层的组织与性能[J]. 中国激光, 2020, 47(4): 0402004.

Song Yong, Zhu Wei, Li Sheng, Zhang Cong, Qiu Changjun. Microstructure and Properties of Nitrogenous Austenitic Stainless Steel Prepared Using Laser Cladding[J]. Chinese Journal of Lasers, 2020, 47(4): 0402004.

[1] Hu L, Peng H L, Baker I, et al. Characterization of high-strength high-nitrogen austenitic stainless steel synthesized from nitrided powders by spark plasma sintering[J]. Materials Characterization, 2019, 152: 76-84.

[2] 朱红梅, 李勇作, 张振远, 等. 激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究[J]. 中国激光, 2018, 45(12): 148-153.

Zhu H M, Li Y Z, Zhang Z Y, et al. Mechanical and corrosion properties of martensite/ferrite duplex stainless steel prepared via laser cladding[J]. Chinese Journal of Lasers, 2018, 45(12): 148-153.

[3] 罗开玉, 周阳, 鲁金忠, 等. 激光冲击强化对316L不锈钢熔覆层微观结构和性能的影响[J]. 中国激光, 2017, 44(4): 0402005.

[4] 张聪, 张振远, 邱长军, 等. 含氮双相不锈钢激光成型试样的力学与腐蚀性能[J]. 中国表面工程, 2019, 32(2): 163-169.

Zhang C, Zhang Z Y, Qiu C J, et al. Mechanical and corrosion properties of nitrogen bearing duplex stainless steel sample prepared by laser forming[J]. China Surface Engineering, 2019, 32(2): 163-169.

[5] 杨全占, 魏彦鹏, 高鹏, 等. 金属增材制造技术及其专用材料研究进展[J]. 材料导报, 2016, 30(S1): 107-111, 124.

Yang Q Z, Wei Y P, Gao P, et al. Research progress of metal additive manufacturing technologies and related materials[J]. Materials Review, 2016, 30(S1): 107-111, 124.

[6] Xu YL, Zhou ZJ. Processing and structure of a nitrogen alloyed oxide dispersion strengthened austenitic stainless steel by mechanical alloying[C]. Journal of Physics: Conference Series, 2013, 419( 1): 012052.

[7] Cisneros M M. ValdésE, Vázquez D, et al. Development of austenitic nanostructures in high-nitrogen steel powders processed by mechanical alloying[J]. Metallurgical and Materials Transactions A, 2002, 33(7): 2139-2144.

[8] Gavriljuk VG, BernsH. High nitrogen steels[M]. Berlin, Heidelberg: Springer-Verlag, 1999: 215- 218.

[9] BernsH, EulU, HeitzE, et al., 1999, 318/319/320: 517- 522.

[10] Nakanishi T, Tsuchiyama T, Mitsuyasu H, et al. Effect of partial solution nitriding on mechanical properties and corrosion resistance in a type 316L austenitic stainless steel plate[J]. Materials Science and Engineering: A, 2007, 460: 186-194.

[11] 郭卫, 张亚普, 柴蓉霞. 单道次激光熔覆304不锈钢数值模拟与实验研究[J]. 激光与光电子学进展, 2019, 56(9): 091401.

[12] Zhu H C, Jiang Z H, Li H B, et al. Effects of nitrogen segregation and solubility on the formation of nitrogen gas pores in 21.5Cr-1.5Ni duplex stainless steel[J]. Metallurgical and Materials Transactions B, 2017, 48(5): 2493-2503.

[13] 卢世静, 孙斐, 缪小吉, 等. 离子渗氮和固溶复合处理制备深层含氮奥氏体不锈钢[J]. 表面技术, 2018, 47(10): 180-185.

Lu S J, Sun F, Miao X J, et al. Preparation for deep nitriding austenitic stainless steel by complex treatment of plasma nitriding and solid solution[J]. Surface Technology, 2018, 47(10): 180-185.

[14] NakamuraY, NakajimaM, ShimizuT, et al., 2012, 525/526: 217- 220.

[15] LiX, Wei YH, Wei ZY, et al. Effect of cold rolling on microstructure and mechanical properties of AISI 304N stainless steel[C]. IOP Conference Series: Earth and Environmental Science, 2019, 252( 2): 022027.

[16] Li C, Bell T. Sliding wear properties of active screen plasma nitrided 316 austenitic stainless steel[J]. Wear, 2004, 256(11/12): 1144-1152.

[17] Chen G Q, Wei Y H, Li S, et al. Friction and wear mechanism of unlubricated 304L austenitic stainless steel at room temperature[J]. Journal of Wuhan University of Technology (Materials Science Edition), 2012, 27(2): 222-226.

[18] 金维松. 含氮奥氏体不锈钢耐局部腐蚀性能的研究[D]. 昆明: 昆明理工大学, 2007: 32- 55.

Jin WS. Study on local corrosion resistance of nitrogenous austenitic stainless steel[D]. Kunming: Kunming University of Science and Technology, 2007: 32- 55.

[19] Qin X J, Guo X L, Lu J Q, et al. Erosion-wear and intergranular corrosion resistance properties of AISI 304L austenitic stainless steel after low-temperature plasma nitriding[J]. Journal of Alloys and Compounds, 2017, 698: 1094-1101.

[20] Lu S J, Zhao X B, Wang S K, et al. Performance enhancement by plasma nitriding at low gas pressure for 304 austenitic stainless steel[J]. Vacuum, 2017, 145: 334-339.

宋勇, 朱伟, 李胜, 张聪, 邱长军. 激光熔覆含氮奥氏体不锈钢层的组织与性能[J]. 中国激光, 2020, 47(4): 0402004. Song Yong, Zhu Wei, Li Sheng, Zhang Cong, Qiu Changjun. Microstructure and Properties of Nitrogenous Austenitic Stainless Steel Prepared Using Laser Cladding[J]. Chinese Journal of Lasers, 2020, 47(4): 0402004.