不锈钢薄板激光搭接焊接头的力学性能  下载: 964次

下载: 964次

梁行, 阚盈, 姜云禄, 陈怀宁. 不锈钢薄板激光搭接焊接头的力学性能[J]. 中国激光, 2018, 45(6): 0602001.

Hang Liang, Ying Kan, Yunlu Jiang, Huaining Chen. Mechanical Properties of Laser Overlap Welded Joints of Stainless Steel Sheets[J]. Chinese Journal of Lasers, 2018, 45(6): 0602001.

[1] 史春元, 顾国臣, 王洪潇, 等. 不锈钢车体非熔透激光搭接焊热源模型[J]. 焊接学报, 2011, 32(5): 85-88.

史春元, 顾国臣, 王洪潇, 等. 不锈钢车体非熔透激光搭接焊热源模型[J]. 焊接学报, 2011, 32(5): 85-88.

Shi C Y, Gu G C, Wang H X, et al. Heat source model for partial penetration lap laser welding of stainless steel railway vehicles[J]. Transactions of the China Welding Institution, 2011, 32(5): 85-88.

[3] 方洪渊. 焊接结构学[M]. 北京: 机械工业出版社, 2008: 56- 57.

方洪渊. 焊接结构学[M]. 北京: 机械工业出版社, 2008: 56- 57.

Fang HY. Welding[M]. Beijing: China Machine Press, 2008: 56- 57.

Fang HY. Welding[M]. Beijing: China Machine Press, 2008: 56- 57.

[4] TakashiroyukiM. Laser welding techniques of stainless steel vehicle body[J]. Foreign Locomotive & Rolling Stock Technology, 2007( 5): 4- 5.

TakashiroyukiM. Laser welding techniques of stainless steel vehicle body[J]. Foreign Locomotive & Rolling Stock Technology, 2007( 5): 4- 5.

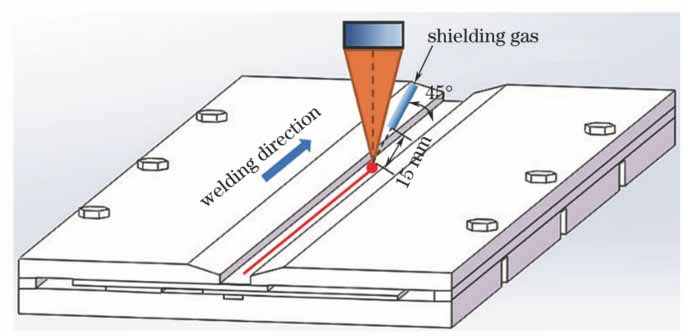

[5] 周媛, 蔡艳, 衡昊坤, 等. 侧吹气体对奥氏体不锈钢激光焊缝组织和耐腐蚀性能的影响[J]. 中国激光, 2017, 44(5): 0502005.

周媛, 蔡艳, 衡昊坤, 等. 侧吹气体对奥氏体不锈钢激光焊缝组织和耐腐蚀性能的影响[J]. 中国激光, 2017, 44(5): 0502005.

[6] 刘佳. 轨道客车用SUS301L奥氏体不锈钢激光叠焊技术研究[D]. 长春: 长春理工大学, 2011: 1- 11.

刘佳. 轨道客车用SUS301L奥氏体不锈钢激光叠焊技术研究[D]. 长春: 长春理工大学, 2011: 1- 11.

LiuJ. Research on laser lap welding technology of SUS301L austenitic stainless steel for railway vehicles[D]. Changchun: Changchun University of Science and Technology, 2011: 1- 11.

LiuJ. Research on laser lap welding technology of SUS301L austenitic stainless steel for railway vehicles[D]. Changchun: Changchun University of Science and Technology, 2011: 1- 11.

[7] 邢孟琪, 李铸国, 孙军浩, 等. 细管径侧吹气体流量对光纤激光中厚板焊接的影响[J]. 中国激光, 2017, 44(3): 0302012.

邢孟琪, 李铸国, 孙军浩, 等. 细管径侧吹气体流量对光纤激光中厚板焊接的影响[J]. 中国激光, 2017, 44(3): 0302012.

[8] 李竹洁, 吕俊霞, 邹江林, 等. 氮气保护不锈钢激光焊接接头组织及力学性能[J]. 中国激光, 2016, 43(12): 1202006.

李竹洁, 吕俊霞, 邹江林, 等. 氮气保护不锈钢激光焊接接头组织及力学性能[J]. 中国激光, 2016, 43(12): 1202006.

[9] 唐舵, 王春明, 田曼, 等. SUS301L-HT不锈钢激光焊接与MIG焊接对比试验研究[J]. 中国激光, 2015, 42(7): 0703003.

唐舵, 王春明, 田曼, 等. SUS301L-HT不锈钢激光焊接与MIG焊接对比试验研究[J]. 中国激光, 2015, 42(7): 0703003.

[10] 韩晓辉, 陈静, 阚盈, 等. 不锈钢薄板非熔透激光搭接焊热源模型[J]. 中国激光, 2017, 44(5): 0502002.

韩晓辉, 陈静, 阚盈, 等. 不锈钢薄板非熔透激光搭接焊热源模型[J]. 中国激光, 2017, 44(5): 0502002.

[11] Khalid MH, KatayamaS. Fiber laser welding of AISI 304 stainless steel plates[C]. Quarterly Journal of the Japan Welding Society, 2009, 27( 2): 69- 73.

Khalid MH, KatayamaS. Fiber laser welding of AISI 304 stainless steel plates[C]. Quarterly Journal of the Japan Welding Society, 2009, 27( 2): 69- 73.

[14] 刘键, 石岩, 刘佳, 等. 保护气体对奥氏体不锈钢激光焊接的影响[J]. 激光与光电子学进展, 2014, 51(5): 051402.

刘键, 石岩, 刘佳, 等. 保护气体对奥氏体不锈钢激光焊接的影响[J]. 激光与光电子学进展, 2014, 51(5): 051402.

[15] 梁行, 姜云禄, 陈怀宁, 等. 残余应力对薄板激光搭接接头力学性能影响[J]. 焊接学报, 2017, 38(10): 112-116.

梁行, 姜云禄, 陈怀宁, 等. 残余应力对薄板激光搭接接头力学性能影响[J]. 焊接学报, 2017, 38(10): 112-116.

Liang H, Jiang Y L, Chen H N, et al. Effect of residual stress on mechanical properties of sheet laser overlap welding joints[J]. Transactions of the China Welding Institution, 2017, 38(10): 112-116.

[16] 赵瑞荣, 阚盈, 姜云禄, 等. 考虑残余应力的激光搭接焊接头拉伸和疲劳试样宽度标准化[J]. 焊接, 2017( 2): 40- 43.

赵瑞荣, 阚盈, 姜云禄, 等. 考虑残余应力的激光搭接焊接头拉伸和疲劳试样宽度标准化[J]. 焊接, 2017( 2): 40- 43.

Zhao RR, KanY, Jiang YL, et al. Standardized width of tensile and fatigue specimens of laser lap welded joints considering residual stress[J]. Welding & Joining, 2017( 2): 40- 43.

Zhao RR, KanY, Jiang YL, et al. Standardized width of tensile and fatigue specimens of laser lap welded joints considering residual stress[J]. Welding & Joining, 2017( 2): 40- 43.

[17] 朱国仁, 陈松, 李蒙蒙. SUS301L不锈钢非熔透型激光搭接焊的疲劳特性分析[J]. 焊接学报, 2016, 37(4): 14-18.

朱国仁, 陈松, 李蒙蒙. SUS301L不锈钢非熔透型激光搭接焊的疲劳特性分析[J]. 焊接学报, 2016, 37(4): 14-18.

Zhu G R, Chen S, Li M M. Study on fatigue performance of stainless steel non-penetration laser lap welding of SUS301L stainless steel body[J]. Transactions of the China Welding Institution, 2016, 37(4): 14-18.

[18] General Administration of Quality Supervision, InspectionandQuarantine of the People's Republic of China: GB/T 31218-2014[S]GB/T 31218-2014[S].Beijing: China Standard Press, 2014.

General Administration of Quality Supervision, InspectionandQuarantine of the People's Republic of China: GB/T 31218-2014[S]GB/T 31218-2014[S].Beijing: China Standard Press, 2014.

[19] 于孟, 张清东, 何汝迎, 等. 冷轧SUS301和SUS304不锈钢表面硬度控制工艺优化研究[J]. 钢铁, 2010, 45(1): 64-69.

于孟, 张清东, 何汝迎, 等. 冷轧SUS301和SUS304不锈钢表面硬度控制工艺优化研究[J]. 钢铁, 2010, 45(1): 64-69.

Yu M, Zhang Q D, He R Y, et al. Surface hardness control technique for SUS301 and SUS304 stainless strip cold rolling[J]. Iron and Steel, 2010, 45(1): 64-69.

梁行, 阚盈, 姜云禄, 陈怀宁. 不锈钢薄板激光搭接焊接头的力学性能[J]. 中国激光, 2018, 45(6): 0602001. Hang Liang, Ying Kan, Yunlu Jiang, Huaining Chen. Mechanical Properties of Laser Overlap Welded Joints of Stainless Steel Sheets[J]. Chinese Journal of Lasers, 2018, 45(6): 0602001.