The guiding of light is a valuable challenge for the industry. Many studies have been done according to many parameters like efficiency, health ambient, and design[13" target="_self" style="display: inline;">–3]. The hollow cylindrical prismatic light guide (CPLG) has the shape of a transparent light guide whose walls are composed of extruded prisms[4]; they offer a technical alternative as light transport in standard tubular reflective guidance systems. The hollow light guide is internally covered with prismatic film whose outer face is composed of a 90° microprismatic structure longitudinal to the axis of the guide. Light suffers total internal reflection (TIR) in the prismatic structure, which has been developed and manufactured using dielectric materials. During the last few years, diverse geometrical and photometrical analyses were proposed due to the need for the optimization and manipulation of the light output and its distribution in several applications[5,6]. Different studies have been done in order to prove experimentally that the standards of quality of prismatic guides are high enough to compete favorably with other available types of light guides, like aluminum ones, in which light suffers from an intrinsic loss of energy at each surface reflection. In light guidance structures like fiber optic guides, the optical radiation can waste its energy within a dielectric structure[7,8]. In contrast, the CPLG is an optically ideal device from the point of view of the propagation of light[4].

Prismatic films are composed of microprismatic structures whose width is usually of the order of several hundred micrometers and are usually made of acrylic resin materials or clear grade optic polycarbonate.

Considerations related to light losses of prism film are very important from the point of view of the long distance transmission of light. Although such light guides can be fairly efficient, losses in prism light guides are influenced by absorption, scattering, attenuation coefficients, and optical imperfections[9,10]. Hence, it is important to consider the following imperfections of the surfaces of the prismatic microstructure: surfaces that are not optically flat or that deviate from the expected angle, optical inhomogeneities in the material, and the existence of surface irregularities on the prism peaks that could modify the optical behavior of the prismatic film. Furthermore, there are mechanical deformations on the prismatic surfaces due to the induced bend in the prismatic film. This Letter provides a characterization method based on experimental measurements in order to obtain the deformation rate in the geometry for different bendings of the prismatic film used in hollow CPLGs. The influence of the light losses affected by deformation has been evaluated.

This Letter is organized as follows. First, an experimental recognition procedure algorithm was developed in order to measure the deformation in the geometry of the prism structure of a prismatic film sheet for different curvatures by image processing techniques. The curvature of a circle of radius is defined to be the reciprocal of the radius (). We apply the Hough transform (HT)[11] to a line-enhanced binary image to generate a Hough domain image for detecting lines and angles associated with curvature defects. After that, experimental procedures and software simulations were carried out to quantify luminous flux losses due to mechanical deformations. Finally, conclusions and future developments are presented.

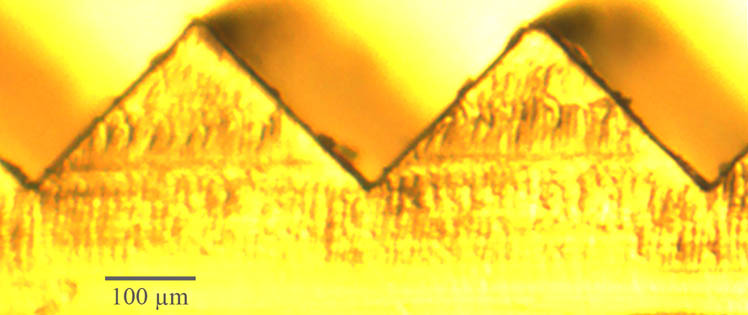

CPLGs can have diameters ranging from 3 to 50 cm and their length varies from 1 m to more than 20 m for larger-diameter guides. They can be produced in a variety of sizes that may be required for specific applications. To predict the reproducibility in the output flux, and then optimize the design, we define the angle deformation range of a prismatic structure with diameter changes. By considering different stages of one experimental deformation process, it is possible to compute the incremental changes associated with . In order to investigate the defects of prismatic structures in the system, computer analysis such as changes in prism angle, defined as the angle between flat surfaces, and plane shape were carried out in the following different curvatures of prismatic film: 0 (plane), 6.67, 10.00, 20.00, 40.00, 57.14, and . For this purpose, the profile of a prismatic film sample with the desired curvature was analyzed by digital imaging processing (Fig. 1). The optical lighting film has a base of 356 μm wide and its peak height is 178 μm.

Fig. 1. Image of a cross section of the prism film used to analyze the contour ().

下载图片 查看所有图片

A precision cutting was performed on a transverse section of the film to avoid damaging the material. After that, the sample was covered by evaporating magnesium oxide onto the surface in order to improve the image contrast and to avoid the error caused by the lighting in the changes of curvature.

By processing the image of the prism profile and using morphological operations, measurement of the inclination angle of the profile can be achieved with high accuracy. The optical microscope used to obtain the prism image is a Motic SMZ-143 equipped with a digital camera (Moticam 2000).

The HT is an effective technique for detecting and finding the images within noise in straight-line detection. We applied the HT for prism angle detection. First, a threshold is applied to the input image in order to make it binary. The threshold value of a binary image is determined from a gray-level histogram of the image and later the edge is separated from the background. The profile edge description is obtained from the Canny operator[12], this operator considers optimal edge objects and hard edges. The Canny method finds edges by looking for the local maxima of the gradient of the image; the gradient is calculated using the derivative of a Gaussian filter. The method uses two thresholds to detect strong and weak edges, and includes the weak edges in the output only if they are connected to strong edges. Later, we used the HT to detect the parameters that control the accuracy of the right angle at the vertex of the prism. The HT is used to identify the parameters of the line and it uses the parametric representation of a straight line , where is the slope or gradient of the line, is the -intercept of the line, the point where the graph of the line crosses the axis, and is the independent variable of the function . This parameter is fitted to a set of given edge points (see Fig. 2). Figure 1 shows the plot of the prismatic film profile with Hough lines identified through digital processing for prism film curvature of in red color.

Fig. 2. Edge map (black color) with Hough lines identified (red color) in a prismatic film profile with a curvature of .

下载图片 查看所有图片

After that, the HT uses a polar representation , where indicates the perpendicular distance from the origin, located at (1,1), to the line and is the angle in which it is shown the sum of intensities in the image peaks. It takes as input the gray scaled image, and produces as output an image showing the positions of tracked intensity discontinuities. The result of the HT is stored in a matrix that can be considered an accumulator (Fig. 3). One dimension of this matrix shows the angles and the other dimension shows the distances . Moreover, each element has a value of the pixels that are positioned on the line with parameters (, ). Thus, the element with the highest value shows the line most represented in the input image. The resolution of the digitization will determine how well we can estimate the gradient of the curve. Therefore, optimum detection features parameters such as rho resolution and theta resolution are selected for object representation. Rho resolution was set at 0.4 to build the accumulation matrix with a jump between two consecutive pixels, and theta resolution was set at 0.05; it represents the spacing of the HT bins along the axis. The HT determines what the features are and how many of them exist in the image. The maximum value in the plane corresponds to the parameters of the straight line with the most amounts of points. The highest peaks located in the HT matrix of the prism film curvature of are shown in Fig. 3. The red square shows the peaks of data in the Hough matrix of the three-prism image used to obtain a mean value. Every peak corresponds to the slope of a prism; the negative angle corresponds to the right slopes of the image and the positive angle corresponds to the left slopes.

Fig. 3. The HT of the three-prism image of a prismatic film curvature of with the Hough peak identified. The red square shows the peaks of data in the Hough matrix and indicates , the perpendicular distance from the origin to the line and is the angle at which the sum of the intensities in the image peaks.

下载图片 查看所有图片

Figure 4(a) shows the relationship between analyzed curvatures and the Hough peak obtained after the HT represented as a prism angle is obtained by the sum of the corresponding positive and negative slopes () of the measurement. The highest peak (Hough peak) of the structure analyzed becomes quite stable from the noncurved film or plane (referenced in the figure as zero curvature) to of curvature; after that, there is an increase of 2.5° (from 89.5° to 92°) in the curvature interval from 20.00 to . A stabilization of 92° is obtained in the last curvature period (from 57.14 to 66.66). Although increasing the number of points that belong to different angles in the contour, the Hough peak remains stable. It is possible to appreciate this phenomenon in the angular deviation rate analysis illustrated in Fig. 4(b). Polycarbonates are thermoplastic polymers that have a linear stress strain behavior at low values of pressure, described by Hook’s laws. However, mechanical response is sensitive to strain rates, especially high strain rates. The pressure applied to the prismatic geometry at curvatures higher than could increase the deformation in the prism geometry causing the gradient change in Fig. 4(a).

Fig. 4. Angle obtained by HT related to the CPLG curvature. The graph legend shows the curvatures evaluated in . Global changes in the prismatic angle related to the Hough peaks are shown in (a) and local changes in prism half-angle in (b).

下载图片 查看所有图片

To accurately determine changes in the prism angle, a detailed analysis of the prismatic apex angle is presented in Fig. 4(b), which shows local changes in prism apex half-angles of several curvatures with regard to the plane prismatic film. A larger angular distance rate around the main half-angles (, 45°, and 0°) is detected for higher values of curvature 20 due to the contour deformation by the increasing number of points that belong to different angles on the edge due to the changes in film curvature. This effect corresponds with the higher increase observed in Fig. 4(a). Deformation is minimal in the optimal slope (positive 45° and negative ), which corresponds with the optimum prism half-angle apex in the figure. In contrast, several peaks appear in nearby values that determine the total prism angle reproduced in Fig. 4(a). Deformation does not increase proportionally with increasing curvature because internal stresses of the material produce asymmetric changes in slope. Although increasing several points that belong to different angles in the contour, the Hough peak remains stable by the prevalence of the angle shown. Hence, we can use HT as a way to classify the deformation of the prism profile.

In this section, we report light losses of experimental and ray-tracing simulations of CPLG to check curvature influence. After that, measurement data are compared to evaluate the performance associated with prismatic light guide curvature.

The light losses of prismatic film used in CPLG, with a range of curvatures from plane to were experimentally measured using physical prototypes on a real size scale to investigate the influence of the curvature of prismatic film in flux transmittance (see Fig. 5). Light output losses of the light guide prototypes, for several curvatures, were experimentally measured using a calibrated laser. The output light beam from a He–Ne laser (JDS Uniphase 1508 helium neon gas laser) with a wavelength of 632.8 nm was optically expanded ten times by a beam expander to be collimated to the desired beam diameter of 4.8 mm. Even though the prismatic film provides minimal spectral changes, by using light of a single wavelength the measurements are independent of the spectral responses of the CPLG. Escaped light is recorded by a photometer (Gamma Scientific’s flexOptometer) with a Si-based detector placed together with the prismatic surface. Light supplied by the He–Ne laser is injected into the plane surface of the prismatic film for incidence angles () over the range of 15° to 45° (5° step size), large enough to evaluate acceptance angle influence () in transmittance measurements[13].

Fig. 5. Experimental setup for the transmittance measurements (upper view).

下载图片 查看所有图片

The angular incidence is determined with regard to the planar surface and the alignment is related to the axis of the prisms, which is in agreement with the axis of the guide. The input flux is controlled by using a 5 mm diameter diaphragm located on the flat surface of the prismatic film.

The flux losses induced by the curvature of each CPLG as a function of the angle of incidence of the collimated beam are shown in Fig. 6. The light flux lost () was estimated by dividing the transmission measurements through the film obtained for each particular curvature of CPLG () by the transmission obtained with the corresponding incident flux (), i.e., light flux obtained with no guide present, .

Fig. 6. Light flux rate (rate of flux lost) scaled from 0 to 1.0 as a function of the curvature of a CPLG for several incidence angles. The graph legend shows incidence angles with regard to the prismatic film flat surface.

下载图片 查看所有图片

The light flux rate escaping through the film is minimum in the plane structure. This escaped light will no longer be guided. After curvature deformation, there is a high increase in flux lost, resulting in a mean loss from 1.5% to 3.2% in the CPLG flux loss, with curvatures higher than 20. Losses increase with increasing incidence angles. For example, for the incidence angle of 30°, which corresponds with the upper incidence angle close to the angle limit for optimum light guiding, there is an increase in losses of 2.3% with regard to plane film. Changes in the direction of the light are intensified with curvatures higher than 33; more complex patterns of optical paths appear related to changes in slopes [see Fig. 4(b)], and thus a slight decrease for the lower incidence angles appears.

Tridimensional simulations were carried out in nonsequential optical ray-tracing software, TracePro 7.6[14], which reproduces the experimental setup previously described. Software simulations allow us to quantify losses due to deformations of the prismatic film surface by comparing with the experimental assembly. Escaped light affected by irregularities in the prism corners and changes in the outer angular portion of the prismatic structure relates to adjusting the curvature and are reproduce in software simulations.

Cylindrical light guides were 3D computer modelled as hollow cylindrical pieces of polycarbonate prism film materials. For this simulation, a sheet with constructive parameters adapted to the prismatic material commercially called OLF (optical lighting film) has been simulated in 3D CAD software. The prism base is 356 μm wide and its height is 178 μm, according to the company datasheet. To check the influence of the curvature in the CPLG, we have designed 3D guides with diverse curvatures, from 8.00 to 57.14. In order to wean light losses caused by changes in the prismatic film curvature, we have situated one detector plane above the peak of the prisms, which records the light flux transmitted through the film. The perfect prism was reproduced, as a perfect prismatic structure; in addition, a corner prism with a 3 μm radius has been set to compute losses due to corner defects. In order to generate a suitable 3D model for a ray-tracing, evaluation is necessary to make some approximation in the geometry profile. In this case, we consider the corners that include the higher width of defects in the cross section as a radius of curvature . This approach is made taking to account the relation of the circle with the radii linearly proportional to a trigonometric function: , where is considered the chord length, is the angle subtended at the center by the chord (90°), and is the radius set by the enrolled circle. The wavelength was set at 632.8 nm in the calculations. The refractive index material of the guide is considered to be 1.59, determined by using a polycarbonate polymer with a linear absorption coefficient of according to the datasheet. The diffraction loss has not been considered[15]. For the simulation, the 3D modeled system is illuminated with a collimated emission pattern of a 4.8 mm diameter spot size. The light source is an emitter that emits above the plane surface of the prismatic film incident above the approximately critical angle of 30°[13]. This acceptance angle limit is determined by the refractive index of the prismatic film.

Changes in curvature are reproduced by the software tools to detect, by comparison with the experimental model, changes in the flux related to the surface deformations of prisms. The main results of simulations with curvatures of 8.00 and 57.14 are presented in Fig. 7, which corresponds with a sample of extreme values experimentally analyzed. The flux loss rate in the film of curvature 8.00 is 1.3%; in the case of 57.14, the change perceived is minimally important, being of the order of 1.5%. Flux losses related to corner defects correspond to 1.3%; the difference between the two curvatures shows it is minimal (0.2%) and corresponds with an induced increase of 1.13° in the outer angular portion of the prismatic structure related to adjusting the curvature of the CPLG.

Fig. 7. Flux loss rate obtained in tridimensional simulations of CPLG guides with curvatures of (a) 8.00 and (b) 57.14.

下载图片 查看所有图片

In terms of comparison with the results of the experimental prototype, we can conclude based on differences between the theoretical and experimental (Fig. 6) that there is a percentage of light loss estimated in due to scratches, cracks, powder, material inhomogeneity, and measurement errors. The theoretical values are smaller than the experimental values and show the influence by surface deformations. In simulations, curvature of shows an increase of lateral losses due to the presence of angles greater than the acceptance angle of the prismatic film [Fig. 7(b)]. This behavior explains the results for curvatures from 44 to 57 (see Fig. 6). In those cases, a fraction of light escapes uncontrollably and consequently errors increase. Several rays suffer additional TIRs on the inner prismatic surfaces, and then some rays undergo multiple reflections on the inner material. In addition, a fraction of the flux is guided inside the guide and escapes outward in subsequent reflections. Additional research is in development to analyze these specific behaviors of ray lights and will be explained in detail in future works.

In conclusion, a new method to assess the influence of the bending-induced mechanical stress of flexible prismatic film used in light guides is proposed. Through a HT algorithm, we evaluate the experimental deformation angle in prisms for pattern detection applied to a sequence of images of prismatic film with different curvatures. According to optical analysis, it is concluded that bending deformation has a raised influence in light guides having diameters from 0.1 to 0.03 m (curvatures from 20 to ). The description of the local and global changes in the prism apex half angle helps us to evaluate the prism deformation through experimental measurements.

Such geometry changes induced by bending give rise to deformation shifts. We analyze how light behaves in response to curvature. Experimental measurements show that light transmission changes in response to curvature provides losses of about 2.4 times in a medium diameter evaluated () for an acceptance angle of 30°. We conclude, based on theoretical considerations, that there is an amount of loss due to defects in the prism corners and small structural changes of the prismatic structure. Experimental comparison allows us to estimate the percentage of light losses due to scratches, cracks, powder, material inhomogeneity, and measurement errors.

It is important to analyze the existence of bending defects in the surface on the prism film that can modify the behavior of light beams and, as a consequence, the rays are directed to other directions instead of undergoing TIR.

Berta García-Fernández, Antonio Álvarez Fernández-Balbuena, Daniel Vázquez-Moliní. Analytical method to measure bending deformations in prismatic optical films[J]. Chinese Optics Letters, 2016, 14(4): 042201.

Download: 787次

Download: 787次