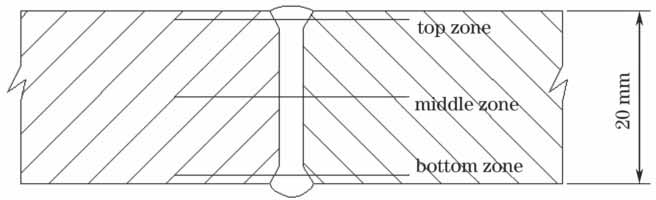

20 mm厚316LN不锈钢板的超高功率光纤激光自熔焊  下载: 795次

下载: 795次

信纪军, 方超, 宋云涛, 卫靖, 吴杰峰, 戴文华. 20 mm厚316LN不锈钢板的超高功率光纤激光自熔焊[J]. 中国激光, 2018, 45(5): 0502007.

Xin Jijun, Fang Chao, Song Yuntao, Wei Jing, Wu Jiefeng, Dai Wenhua. Autogenous Laser Welding of 20-mm-Thick 316LN Stainless Steel Plate by Ultra High Power Fiber Lasers[J]. Chinese Journal of Lasers, 2018, 45(5): 0502007.

[4] FangC, Song YT, WeiJ, et al. Microstructural characteristics of the laser welded joint of ITER correction coil sub case[J]. Fusion Engineering and Design, 2015, 98/99: 1960- 1963.

FangC, Song YT, WeiJ, et al. Microstructural characteristics of the laser welded joint of ITER correction coil sub case[J]. Fusion Engineering and Design, 2015, 98/99: 1960- 1963.

[6] 李竹洁, 吕俊霞, 邹江林, 等. 氮气保护不锈钢激光焊接接头组织及力学性能[J]. 中国激光, 2016, 43(12): 1202006.

李竹洁, 吕俊霞, 邹江林, 等. 氮气保护不锈钢激光焊接接头组织及力学性能[J]. 中国激光, 2016, 43(12): 1202006.

[7] 任勇, 武强, 邹江林, 等. 奥氏体不锈钢光纤激光同轴保护焊接的实时监测[J]. 中国激光, 2017, 44(5): 0502003.

任勇, 武强, 邹江林, 等. 奥氏体不锈钢光纤激光同轴保护焊接的实时监测[J]. 中国激光, 2017, 44(5): 0502003.

[8] 吴世凯, 肖荣诗, 陈铠. 大厚度不锈钢板的激光焊接[J]. 中国激光, 2009, 36(9): 2422-2425.

吴世凯, 肖荣诗, 陈铠. 大厚度不锈钢板的激光焊接[J]. 中国激光, 2009, 36(9): 2422-2425.

[9] 张国伟, 肖荣诗. 60 mm厚304不锈钢板超窄间隙光纤激光焊接接头组织性能研究[J]. 中国激光, 2014, 41(8): 0803007.

张国伟, 肖荣诗. 60 mm厚304不锈钢板超窄间隙光纤激光焊接接头组织性能研究[J]. 中国激光, 2014, 41(8): 0803007.

[16] 陈根余, 夏海龙, 周聪, 等. 高功率光纤激光焊接底部驼峰的机理研究[J]. 中国激光, 2015, 42(2): 0203004.

陈根余, 夏海龙, 周聪, 等. 高功率光纤激光焊接底部驼峰的机理研究[J]. 中国激光, 2015, 42(2): 0203004.

信纪军, 方超, 宋云涛, 卫靖, 吴杰峰, 戴文华. 20 mm厚316LN不锈钢板的超高功率光纤激光自熔焊[J]. 中国激光, 2018, 45(5): 0502007. Xin Jijun, Fang Chao, Song Yuntao, Wei Jing, Wu Jiefeng, Dai Wenhua. Autogenous Laser Welding of 20-mm-Thick 316LN Stainless Steel Plate by Ultra High Power Fiber Lasers[J]. Chinese Journal of Lasers, 2018, 45(5): 0502007.