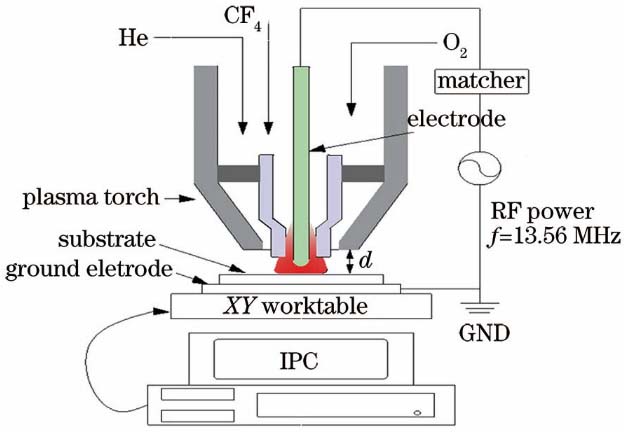

大气等离子体电极结构对碳化硅去除函数的影响  下载: 871次

下载: 871次

宋力, 顿爱欢, 王哲, 吴伦哲, 彭冰, 徐学科. 大气等离子体电极结构对碳化硅去除函数的影响[J]. 中国激光, 2020, 47(10): 1002002.

Song Li, Dun Aihuan, Wang Zhe, Wu Lunzhe, Peng Bing, Xu Xueke. Effects of Atmospheric Pressure Plasma Electrode Structure on Silicon Carbide Removal Function[J]. Chinese Journal of Lasers, 2020, 47(10): 1002002.

[1] 范镝. 碳化硅光学表面抛光机理研究[J]. 激光与光电子学进展, 2012, 49(2): 022202.

[2] 胡赓祥, 蔡珣, 戎咏华. 材料科学基础[M]. 上海: 上海交通大学出版社, 2010: 23- 46.

Hu GX, CaiX, Rong YH. Fundamentals of materials science[M]. Shanghai: Shanghai Jiao Tong University Press, 2010: 23- 46.

[6] 张巨帆, 王波, 董申. 超光滑表面加工方法的新进展[J]. 光学技术, 2007, 33(S1): 150-154.

[7] 张巨帆, 王波, 董申. 大气等离子体抛光技术在超光滑硅表面加工中的应用[J]. 光学精密工程, 2007, 15(11): 1749-1755.

[8] 赵培君. 常温大气等离子抛光去除速度函数的研究[D]. 哈尔滨: 哈尔滨工业大学, 2009: 9- 12.

Zhao PJ. Study of removal rate function of room temperature atmospheric plasma polishing[D]. Harbin: Harbin Institute of Technology, 2009: 9- 12.

[9] Shen X, Deng H, Zhang X, et al. Preliminary study on atmospheric-pressure plasma-based chemical dry figuring and finishing of reaction-sintered silicon carbide[J]. Optical Engineering, 2016, 55(10): 105102.

[10] Sun R, Yang X, Ohkubo Y, et al. Optimization of gas composition used in plasma chemical vaporization machining for figuring of reaction-sintered silicon carbide with low surface roughness[J]. Scientific Reports, 2018, 8(1): 2376.

[11] 苏星. 大气等离子体射流炬设计及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2016: 12- 18.

SuX. Design and study on the atmospheric pressure plasma jet torch[D]. Harbin: Harbin Institute of Technology, 2016: 12- 18.

[12] 史宝鲁. SiC反射镜电弧增强等离子体加工关键技术研究[D]. 长沙: 国防科学技术大学, 2016: 125- 131.

Shi BL. Study on key techniques in arc-enhanced plasma machining for silicon carbide mirrors[D]. Changsha: National University of Defense Technology, 2016: 125- 131.

[13] 王旭. 常压电感耦合等离子体工艺用于加工光学材料的去除函数研究[J]. 中国激光, 2014, 41(8): 0816001.

[14] 徐学基, 诸定昌. 气体放电物理[M]. 上海: 复旦大学出版社, 1996.

Xu XJ, Zhu DC. Gas discharge physics[M]. Shanghai: Fudan University Press, 1996.

[16] 叶换换. 针板电极下大气压脉冲介质阻挡放电模拟研究[D]. 大连: 大连理工大学, 2014: 18- 22.

Ye HH. Numerical study of pulsed dielectric barrier discharge at atmospheric pressure in the needle-plane electrode configuration[D]. Dalian: Dalian University of Technology, 2014: 18- 22.

[17] 卲涛, 严萍. 大气压气体放电及其等离子体应用[M]. 北京: 科学出版社, 2019: 359- 367.

ShaoT, YanP. Atmospheric pressure gas discharge and plasma application[M]. Beijing: Science Press, 2019: 359- 367

[18] Yan Y. Chan-Park M B, Yue C. CF4 plasma treatment of poly(dimethylsiloxane): effect of fillers and its application to high-aspect-ratio UV embossing[J]. Langmuir, 2005, 21(19): 8905-8912.

[19] 李亚茹, 李雪辰, 贾鹏英, 等. 介质阻挡放电羽的等离子体参数光学诊断[J]. 光学学报, 2017, 37(4): 0430002.

宋力, 顿爱欢, 王哲, 吴伦哲, 彭冰, 徐学科. 大气等离子体电极结构对碳化硅去除函数的影响[J]. 中国激光, 2020, 47(10): 1002002. Song Li, Dun Aihuan, Wang Zhe, Wu Lunzhe, Peng Bing, Xu Xueke. Effects of Atmospheric Pressure Plasma Electrode Structure on Silicon Carbide Removal Function[J]. Chinese Journal of Lasers, 2020, 47(10): 1002002.