大口径非球面元件磨削轮廓测量技术研究进展  下载: 1482次

下载: 1482次

席建普, 李彬, 任东旭, 赵则祥. 大口径非球面元件磨削轮廓测量技术研究进展[J]. 激光与光电子学进展, 2018, 55(3): 030008.

Jianpu Xi, Bin Li, Dongxu Ren, Zexiang Zhao. Research Progress of Measurement Technology for Large-Diameter Aspheric Elements on Grinding Stage[J]. Laser & Optoelectronics Progress, 2018, 55(3): 030008.

[1] 杨力. 现代光学制造工程[M]. 北京: 科学出版社, 2009: 5- 10.

YangL. Advanced optical manufacture technology[M]. Beijing: Science Press, 2009: 5- 10.

[2] 尚春民, 张东梅, 张心明. 磨具弯曲成形法非球面研磨的研磨模型[J]. 光电工程, 2012, 39(5): 128-132.

[3] 李圣怡, 戴一帆. 大中型光学非球面镜制造与测量新技术[M]. 北京: 国防工业出版社, 2011: 100- 150.

Li SY, Dai YF. New technology for manufacturing and measurement of large and middle-scale aspheric surfaces[M]. Beijing: National Defense Industry Press, 2011: 100- 150.

[4] TonnellierX, ShoreP, MorantzP, et al. Surface quality of a 1 m Zerodur part using an effective grinding mode[C]. SPIE, 2008, 7102: 71020B.

[5] Andre ML. Status of the LMJ project[C]. SPIE, 1997, 3047: 38- 42.

[6] Stolz CJ. The National Ignition Facility: the world's largest optical system[C]. SPIE, 2007, 6834: 683402.

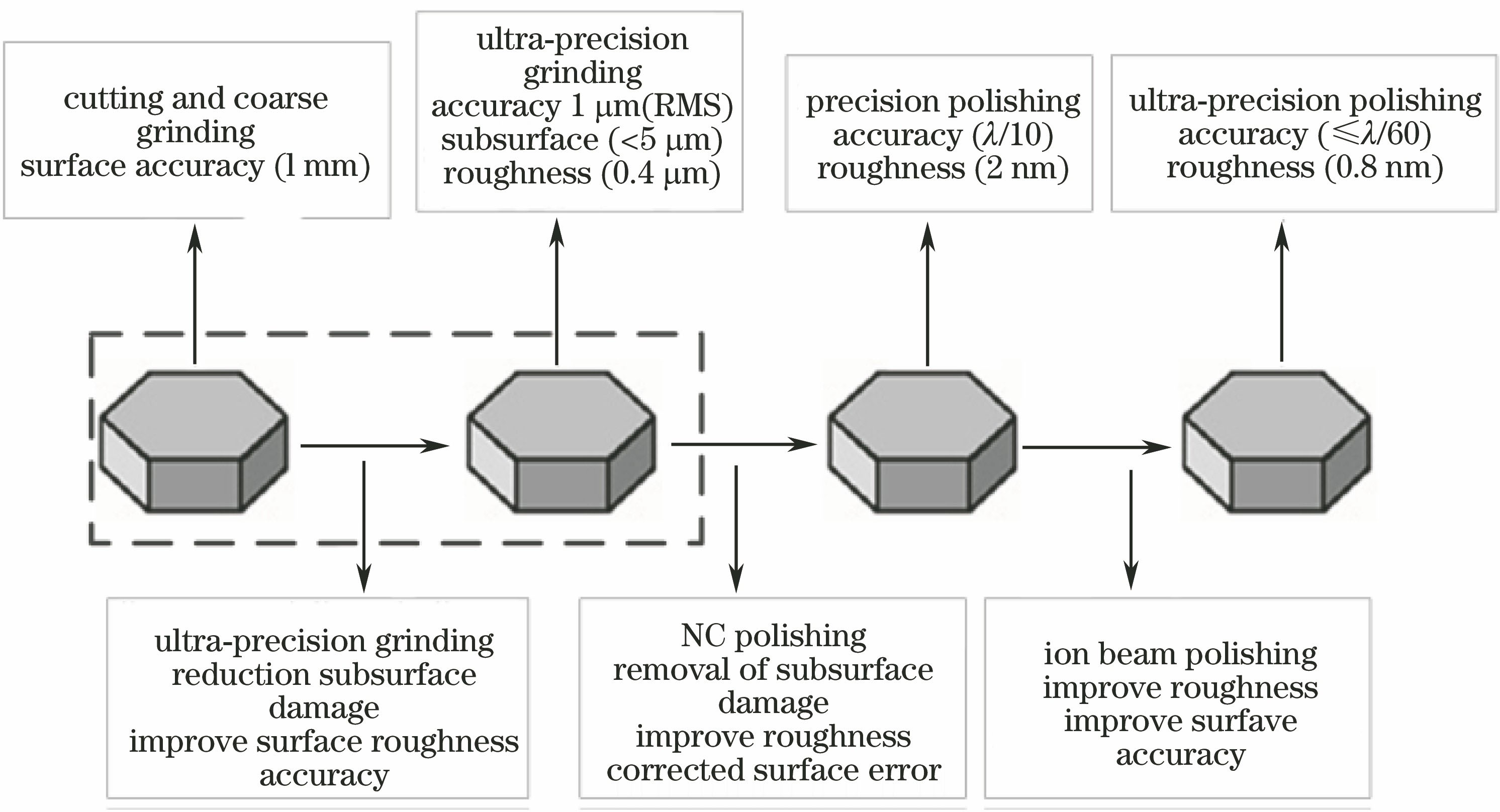

[8] 郭隐彪, 杨炜, 王振忠, 等. 大口径非球面光学元件超精密加工技术与应用[J]. 机械工程学报, 2013, 49(19): 171-178.

Guo Y B, Yang W, Wang Z Z, et al. Technology and application of ultra-precision machining for large size optic[J]. Journal of Mechanical Engineering, 2013, 49(19): 171-178.

[9] 张宪忠, 闫公敬. 基于混合补偿检测-离轴抛物面的方法[J]. 激光与光电子学进展, 2016, 53(12): 121203.

[10] 刘力, 陈新东, 熊玲, 等. 大口径非球面镜检测中激光跟踪仪测角误差研究[J]. 中国激光, 2016, 43(11): 1104003.

[11] Brinksmeier E, Mutlugünes Y, Klocke F, et al. Ultra-precision grinding[J]. CIRP Annals - Manufacturing Technology, 2010, 59(2): 652-671.

[13] 程灏波, 张学军, 郑立功, 等. 非球面研磨阶段检测技术的优化[J]. 航空精密制造技术, 2002, 38(6): 2-3.

Cheng H B, Zhang X J, Zheng L G, et al. Optimization on testing technology for aspherics grinding[J]. Aviation Precision Manufacturing Technology, 2002, 38(6): 2-3.

[14] Sun W. McBride J W, Hill M. A new approach to characterising aspheric surfaces[J]. Precision Engineering, 2010, 34(1): 171-179.

[15] 胡德金. 硬脆非球面光学镜精密磨削与自适应控制方法[J]. 光学学报, 2016, 36(7): 0722004.

[16] Martin HM, Burge JH, Vecchio CD, et al. Optical fabrication of the MMT adaptive, secondary mirror[C]. SPIE, 2000, 4007: 502- 507.

[19] 贾立德, 郑子文, 戴一帆, 等. 摆臂式非球面轮廓仪的原理与试验[J]. 光学精密工程, 2007, 15(4): 499-839.

[20] 贾立德, 郑子文, 李圣怡. 基于柱面坐标系的新型光学坐标测量机的研制[J]. 光学精密工程, 2006, 14(5): 835-504.

[21] 程灏波. 精研磨阶段非球面面形接触式测量误差补偿技术[J]. 机械工程学报, 2005, 41(8): 228-232.

Cheng H B. Touch trigger probe measurement accuracy of aspherical mirror during fine lapping process[J]. Journal of Mechanical Engineering, 2005, 41(8): 228-232.

[22] Zhu YL, Guo YB, LuoW, et al. Design of large-size aspheric measurement system and motion accuracy analysis[C]. SPIE, 2010, 7656: 765620.

[23] 仇谷烽, 郭培基, 懈滨, 等. 接触式非球面轮廓测量的数据处理模型[J]. 光学精密工程, 2007, 15(4): 492-498.

[29] 李洁, 雷向阳, 钟波, 等. 大口径方形非球面镜的高效磨削技术研究[J]. 金刚石与磨料磨具工程, 2011, 31(2): 74-78.

Li J, Lei X Y, Zhong B, et al. Research of high efficiency grinding technology for large square aspheric lens[J]. Diamond & Brasives Engineering, 2011, 31(2): 74-78.

[32] 贺俊, 陈磊. 使用红外干涉仪测量非球面面形[J]. 光学精密工程, 2010, 18(1): 69-74.

[33] 王建明, 郭培基, 仇谷峰. 三坐标轮廓测量仪测量离轴非球面的数据处理[J]. 光学技术, 2013, 39(4): 291-296.

[34] 任同群. 大型非球面检测方法及数据处理研究[D]. 厦门: 厦门大学, 2010.

Ren TQ. The measurement method and data processing of large aspheric surface[D]. Xiamen: Xiamen University, 2010.

[35] TonnellierX. Precision grinding for rapid manufacturing of large optics[D]. Bedfordshire: Cranfield University, 2009.

[36] 郭隐彪, 郭江, 王振忠. 非球面检测路径与高精度曲线拟合算法研究[J]. 中国机械工程, 2008, 19(10): 1201-1204.

Guo Y B, Guo J, Wang Z Z. Study on measuring path and high-precision curve fitting algorithm for axisymmetric aspheric optics[J]. China Mechanical Engineering, 2008, 19(10): 1201-1204.

[37] 张东旭, 杨平, 毕果, 等. 磨削阶段大口径非球面拼接测量技术[J]. 机械工程学报, 2015, 51(4): 22-29.

Zhang D X, Yang P, Bi G, et al. Stitching measurement technique for large-aperture aspheric surface during grinding process[J]. Journal of Mechanical Engineering, 2015, 51(4): 22-29.

[39] 贾立德, 王家伍, 郑子文, 等. 光学非球面面形摆臂式轮廓法测量顶点曲率半径优化算法研究[J]. 仪器仪表学报, 2009, 30(9): 1996-2000.

Jia L D, Wang J W, Zheng Z W, et al. Optimization algorithm for the measurement of vertex radius of aspherics with a swing-arm profilometer[J]. Chinese Journal of Scientific Instrument, 2009, 30(9): 1996-2000.

席建普, 李彬, 任东旭, 赵则祥. 大口径非球面元件磨削轮廓测量技术研究进展[J]. 激光与光电子学进展, 2018, 55(3): 030008. Jianpu Xi, Bin Li, Dongxu Ren, Zexiang Zhao. Research Progress of Measurement Technology for Large-Diameter Aspheric Elements on Grinding Stage[J]. Laser & Optoelectronics Progress, 2018, 55(3): 030008.